Precision Component Manufacturing with CNC Machining

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

This guide will help you prepare your designed parts for 3D printing.

Design for manufacturing, known as DFM, ensures that the components you design can be manufactured, which is crucial for outsourcing. It helps reduce the revisions and turnarounds.

Process and material selection: Material choice is crucial for a product's functionality and aspect. At Norck, we offer three 3D printing processes. Each process uses a different technology with specific materials, advantages, and inconvenience.

a) Fused Deposition Modeling (FDM): FDM 3D printing offers a low-cost component with average accuracy and uses thermoplastics for 3D printing. It is mainly used for small parts with average details and specialized manufacturing tools like fixtures and jigs. A post-process is required to remove any excess material or burrs and to smooth surfaces.

b) Stereolithography (SLA): SLA 3D printing is known for good precision, uniform strength (due to resin polymerization), finer details, and smooth surfaces. The printed models are less rigid than FDM printed models. The cost is higher than FDM as it requires a significant amount of post-processing. It is mainly used for mold prototypes, conceptual models, and jewelry.

c) Selective laser sintering (SLS): SLS 3D printing offers rigid models. Materials used in SLS are more fragile than those used in FDM or SLA. Printed models can be finished using sanding, polishing, or spray coating. It is used for jigs, fixtures, as a replacement for metallic parts, and prostheses.

Norck offers a large selection of 3D printing materials :

|

Family of material |

Material |

|

Thermo-Plastics |

ABS |

|

PC |

|

|

PEEK |

|

|

PETG |

|

|

PLA |

|

|

PVA |

|

|

TPU |

|

|

Resin |

Standard |

|

High-strength |

|

|

Transparent |

|

|

Rubber |

|

|

Flexible |

|

|

Metals |

Titanium |

|

Stainless steel |

|

|

Aluminum |

|

|

Brass |

|

|

Bronze |

|

|

Inconel |

Finishes: We offer the finishes below for your 3D printing components :

- Painting

- Clear part finishing

- Texturing

- Masking

- Thermal curing

- Polishing

To ensure that your designed parts can be manufactured, you must keep the best practices to improve the manufacturability and get high-quality products.

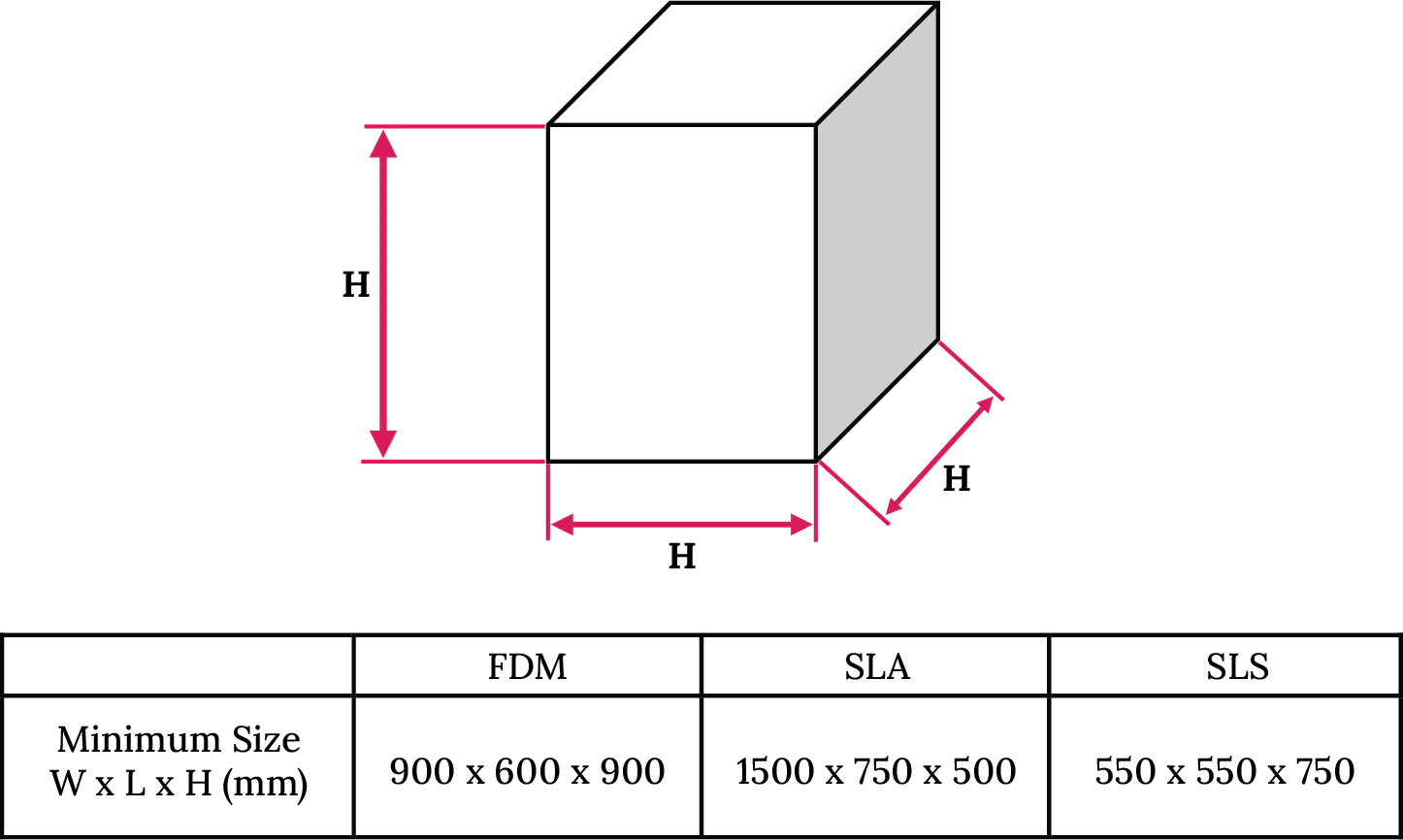

1. Maximum size: We can print parts as big as :

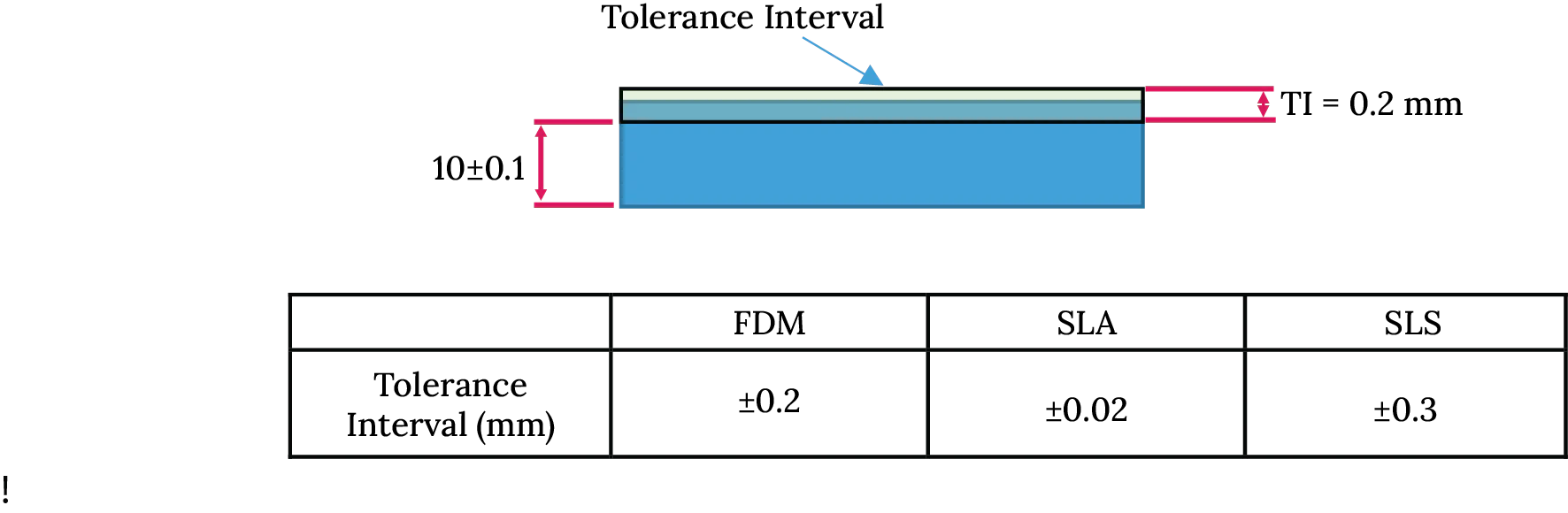

2. Tolerances: It is the deviation of the fabrication from the design. A fabricated part can not be identical to the 3D model. the designer must add tolerances for acceptance called tolerance interval.

For example, a height of a wall is 10mm, called the nominal dimension. Adding tolerance interval to the nominal dimension of ±0.1mm means that any part with thickness from 9.9 to 10.1mm isconsidered acceptable.

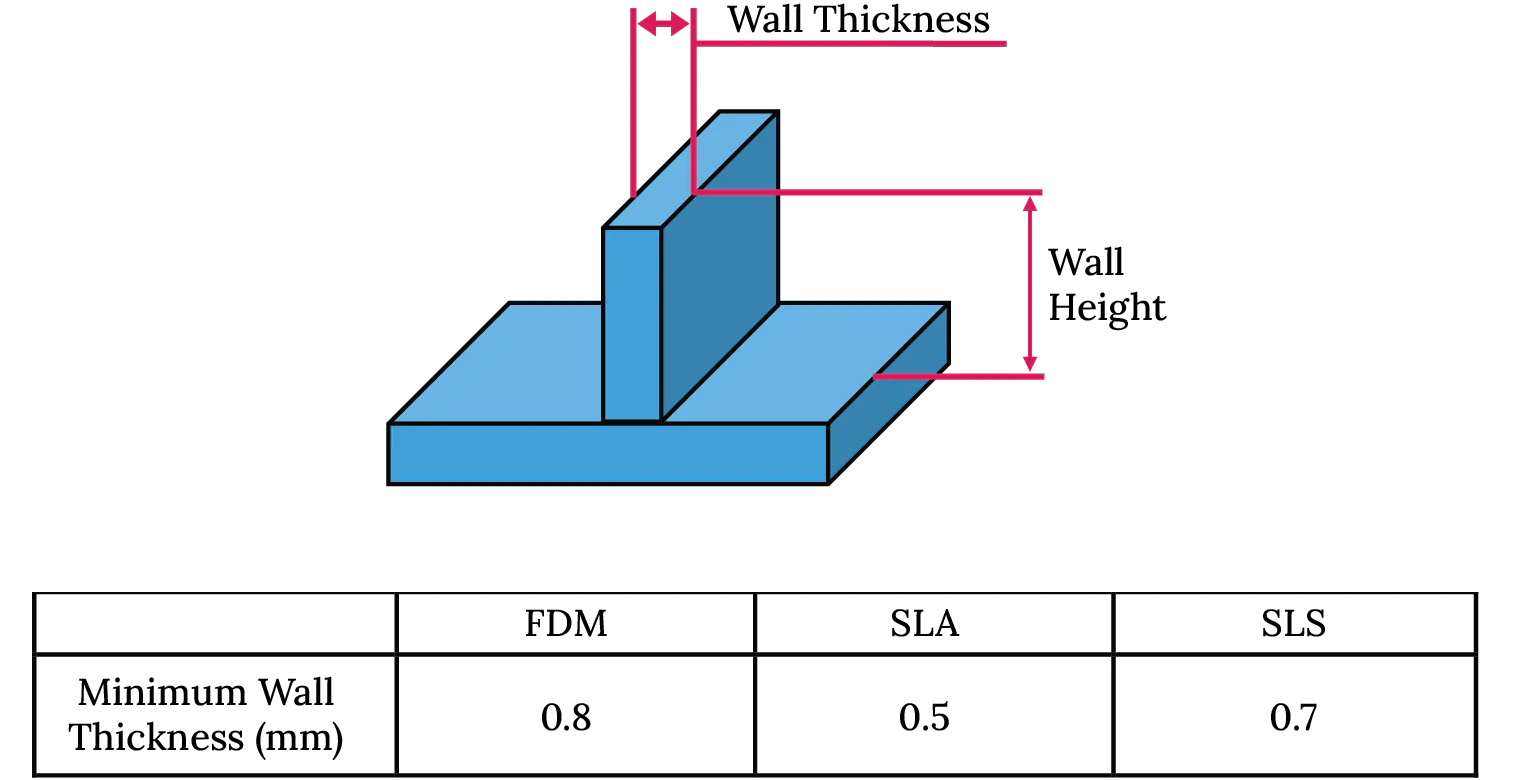

3. Wall thickness and height: Depending on the 3D printing technique, the thickness of walls should be thicker than the minimum wall thickness shown below, and the height shouldn't exceed the maximum height

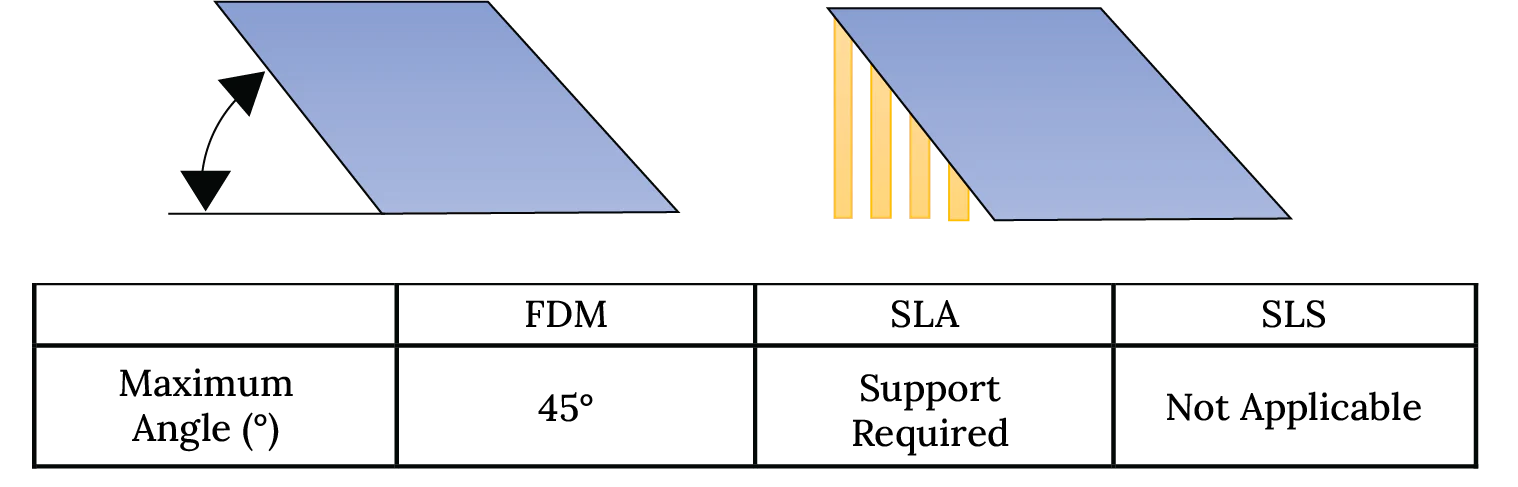

4. Overhangs: In 3D printing,layers are laid upon existing material. The layers laying over no existing material are called overhangs. Depending on the 3D printing method, overhangs greater than certain degrees will need support.

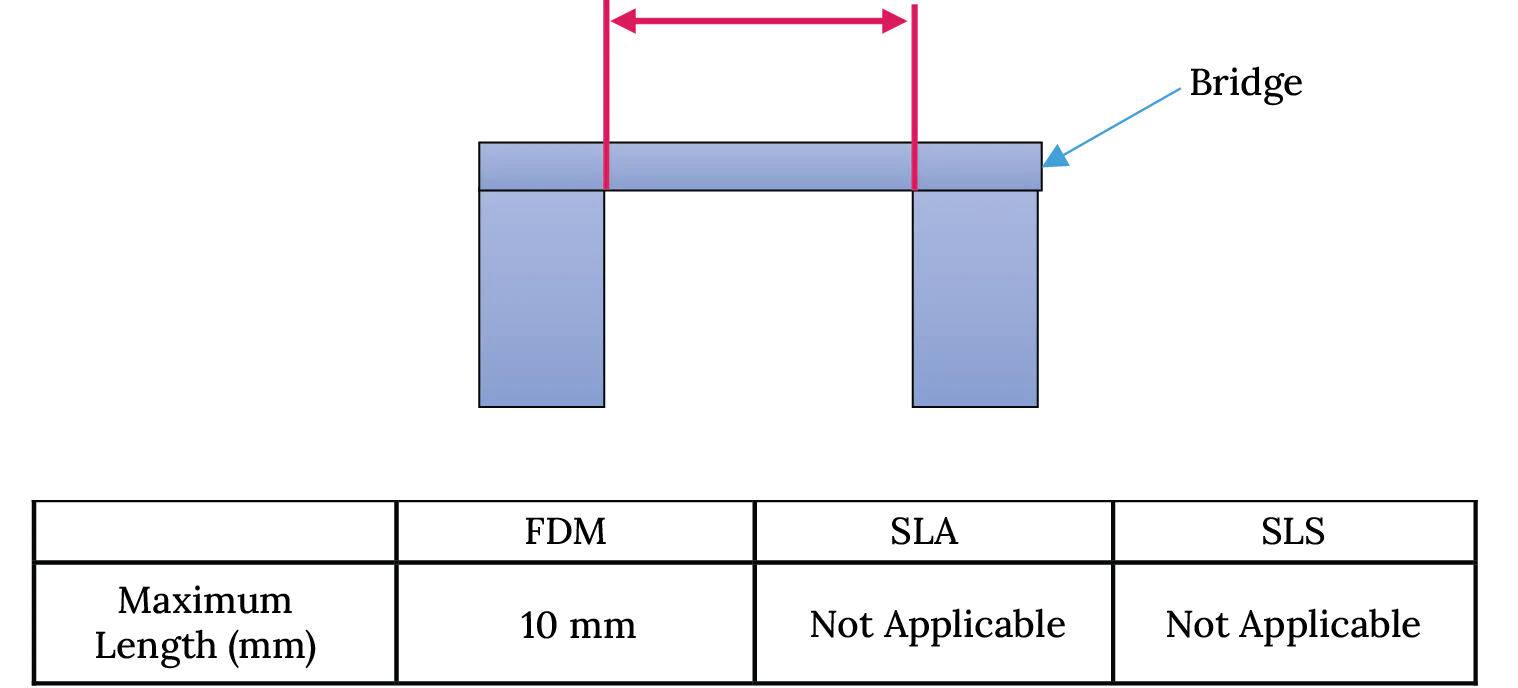

5. Bridges: Bridges connect walls without needing support when they are under the maximum length. For longer bridges, it is necessary to add bridges.

6. Clearances: In 3D printing, it is possible to print whole functional assemblies or several parts. We recommend leaving 0.4mm between components.

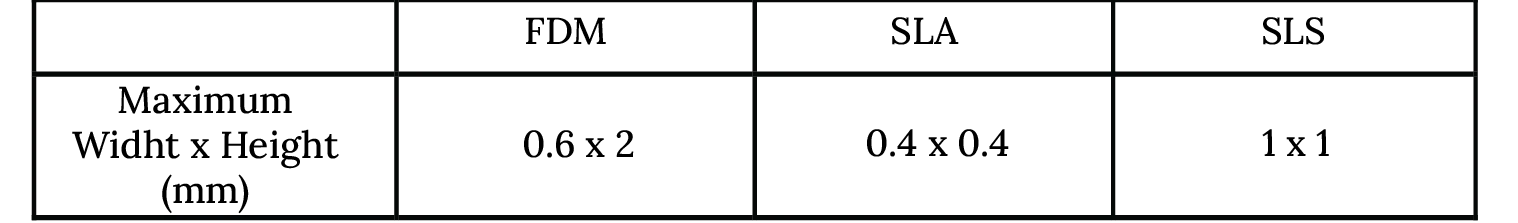

7. Embossed & engraved details: Embossedand engraved onesshould not exceed maximum depth and width.

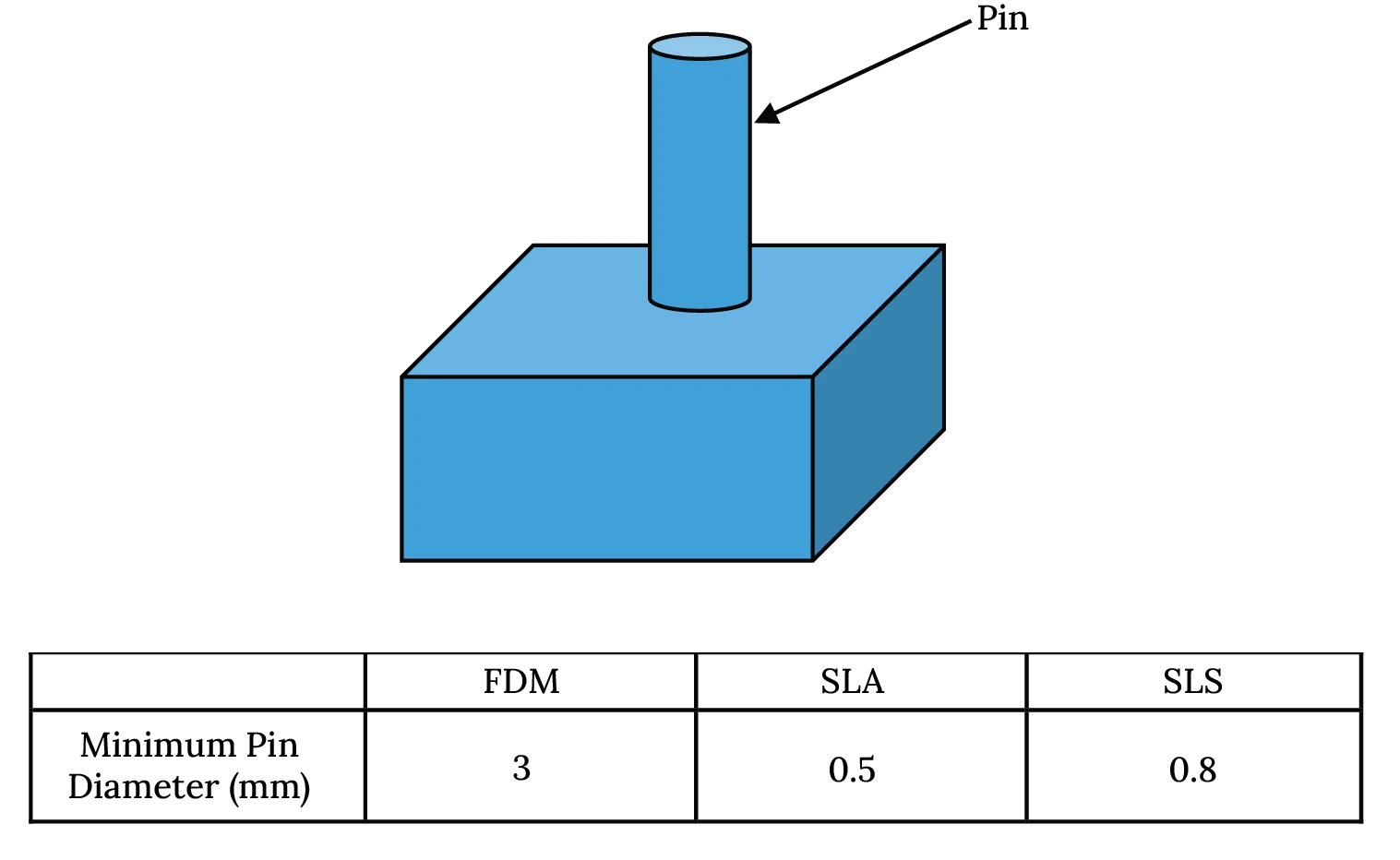

8. Pin diameter: Pin features should not be thinner than the dimensions below.

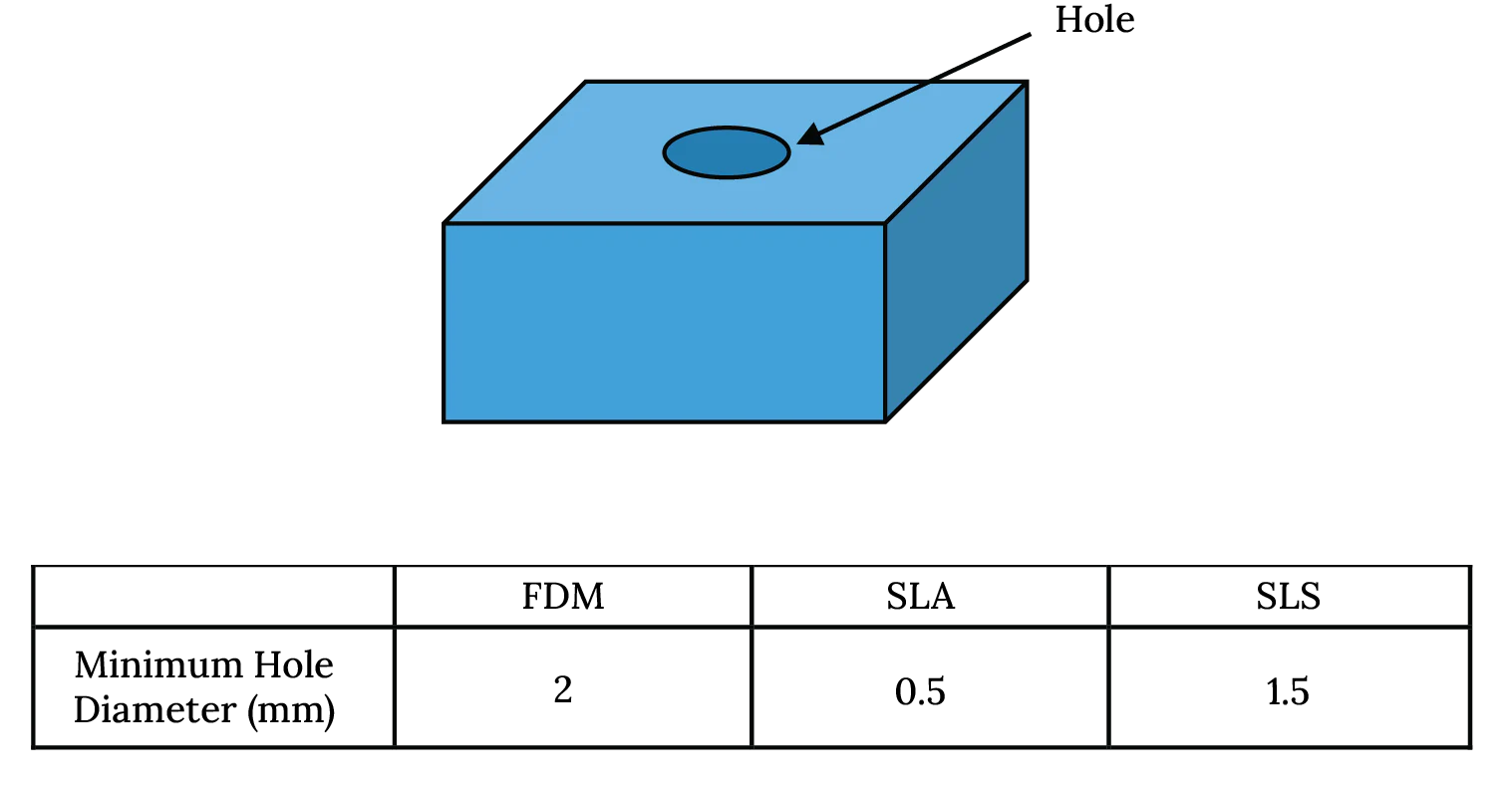

9. Holes: The minimumdiameters of holesare below.

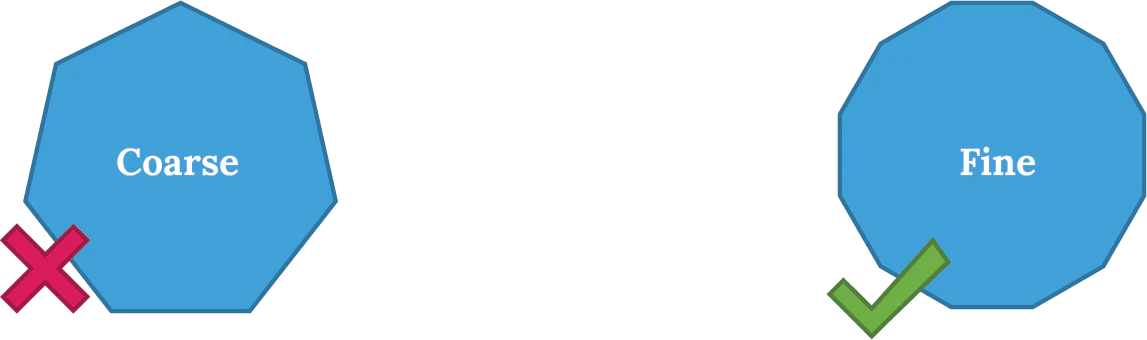

10. File resolution: When saving a 3D model as STL, we recommend increasing the detail level, usingthe fine option instead of the coarse. Fine STL files have smoother surfaces.

11. Threads: Avoid rectangular threads to minimize stress. We recommend using trapezoidal section threads and screws. The minimal thread size is 1mm

Unlock the vast mount of CNC machining capacity with Norck for custom component manufacturing, precision metal and plastic manufacturing.

Whether you need 3D-printed parts in plastic or metal, Norck has the right capacity and solution for you.

Thousands of companies around the world rely on Norck's vast capacity and its extremely qualified capabilities to get their sheet metals fabricated.

Norck's advanced technical and technological capabilities make it one of the most on-demand sheet metal fabrication companies across the world.

Norck provides precision CNC cutting services such as laser cutting, plasma cutting, and waterjet cutting.

Norck's on-demand 3D printing and additive manufacturing services include nearly all 3D printing methods and technologies.

Norck's capabilities include state-of-the-art CNC machineries available for our customers.