What is Waterjet cutting?

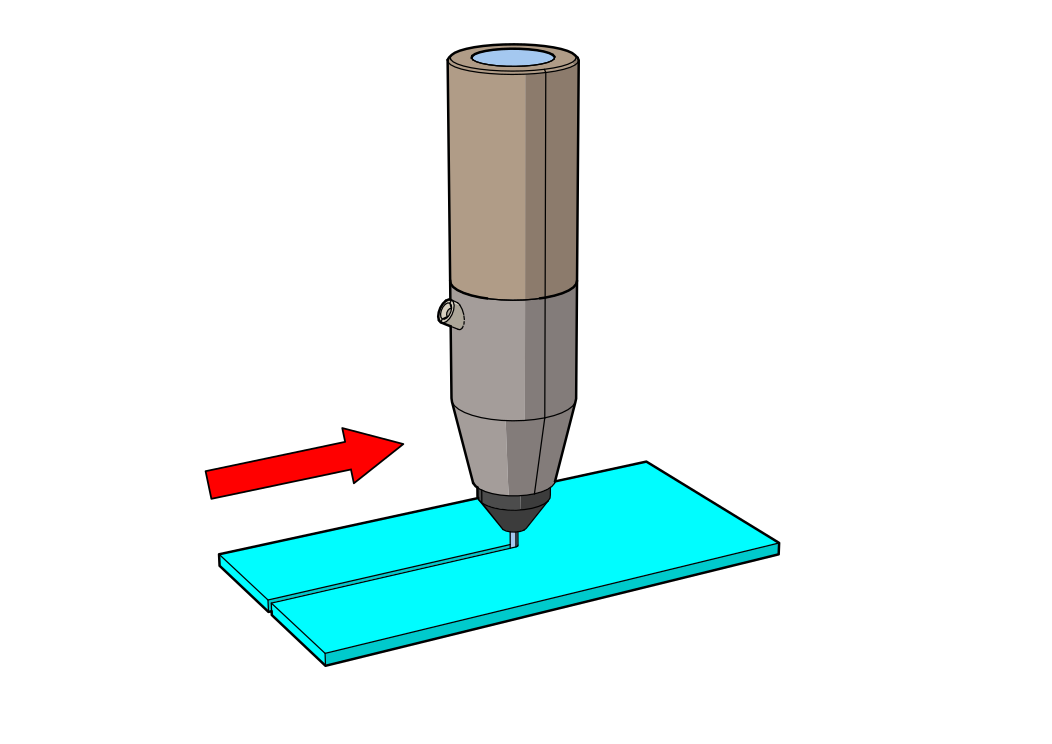

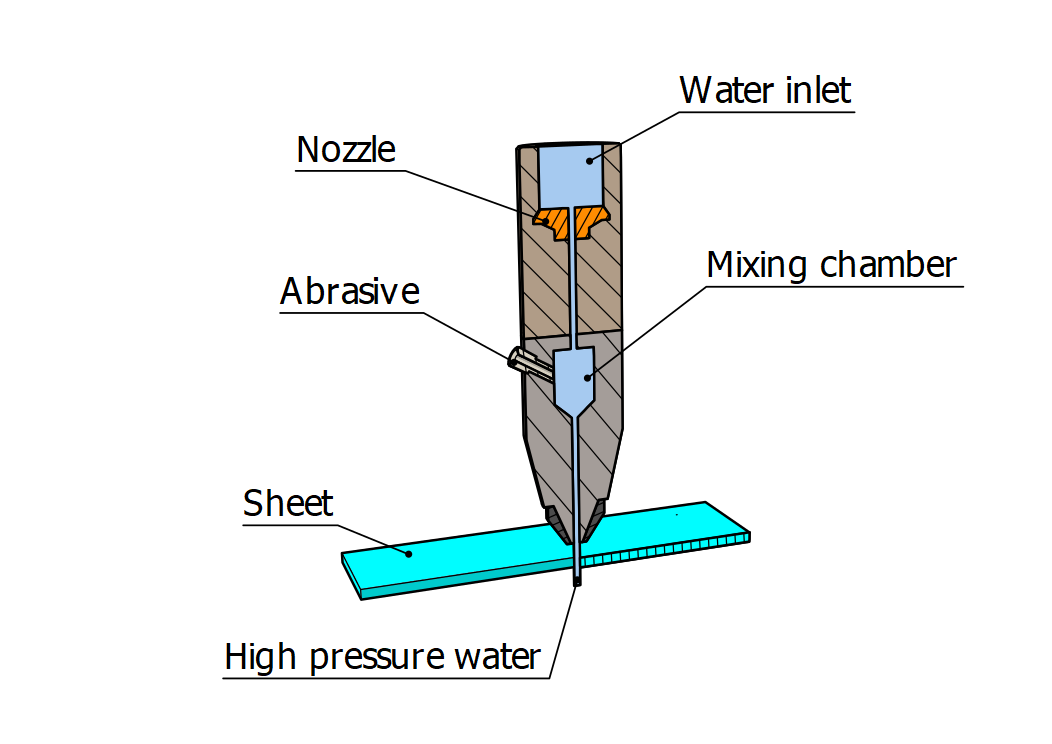

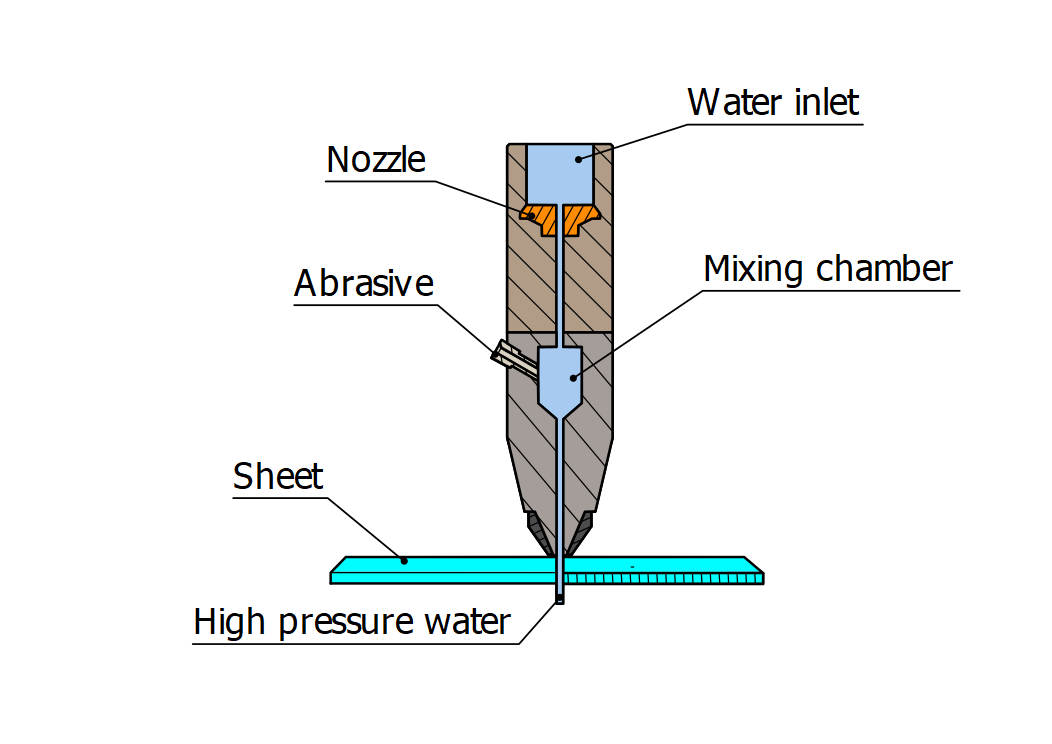

Waterjet cutting is a process that uses high-pressure water, generally with abrasive particles, to cut through various materials such as metals, plastics, and stones. Abrasive particles are added to the water stream to increase its cutting force for hard materials. It is used in aerospace, naval, automotive, ceramics, and textile.

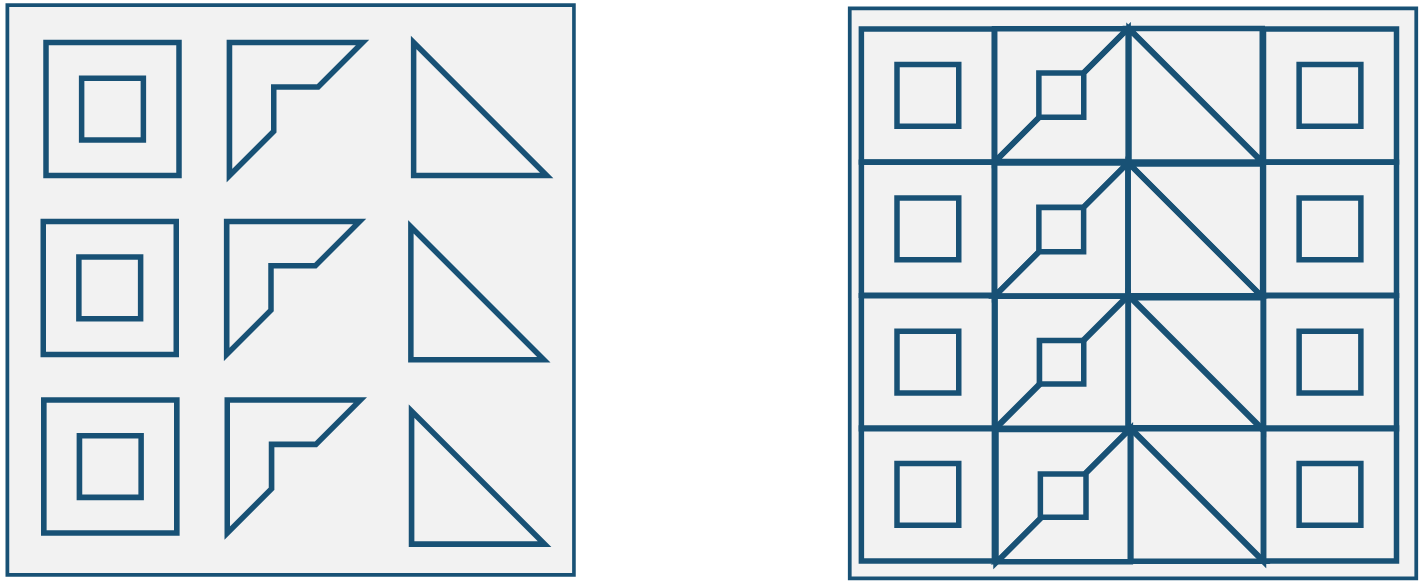

Waterjet cutting can cut tubes and bent sheet metal components to clean edges and add holes.

Waterjet cuts are perpendicular to the sheet surface and can't add draft or threads.

What are the benefits of using waterjet cutting?

Waterjet cutting offers more advantages over the traditional cutting process:

• More precision: Accuracy is around ±0.004in (±0.1mm), while in conventional methods, it is about 0.04in(±1mm)

• Clean: Cuts with no burrs or double edges

• Faster manufacturing: Since it is controlled via a computer

Even over laser cutting waterjet offers:

• Cold cutting, the material will not be affected by heat

• No pollution since it doesn't use cutting gases

• Greater thickness can be cut using waterjet cutting than laser cutting

Using abrasive, waterjet cutting machines can cut through ferrous and non-ferrous rigid materials such as metals, ceramics, marbles, and tempered glass. And without any abrasive for materials such as plastics, fiberglass, and cardboard. Waterjet can cut through different thicknesses. It is used to cut simple or complex shapes with ease and an accuracy of 0.1mm, while traditional cutting processes' accuracy is about ±1mm. It is an efficient and low labor cost process.

Norck: Your Data-Driven Partner for On-Demand Manufacturing Excellence

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

- AI-Powered Manufacturing: Data and AI optimize our processes for superior quality, minimized costs, and supply chain visibility

- Vast Production Capacity: Our extensive partner network in Europe and the US guarantees both low and high-volume production.

- End-to-End Expertise: Our team of engineers, data scientists, and product developers ensure design for manufacturability and unparalleled service

- Single-Source Solution: Norck streamlines your supply chain, reduces overhead, enhances purchasing power, and delivers just-in-time results.

- Online Waterjet Cutting Services: Norck's online waterjet cutting services provide a fast, easy, and reliable way to bring your ideas to life with high quality, custom made parts.

- Waterjet Cutting Services Near You: Your search for waterjet cutting services ends here. Norck offers tailored engineering and manufacturing support that begin with your unique project needs. Whether you're a local business or searching online, our expert team delivers top-quality, customized waterjet cutting solutions to bring your designs to life.

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

English

English