Norck: Your Path to DMLS Precision and Innovation

Norck delivers expertly manufactured components using Direct Metal Laser Sintering (DMLS) for unmatched design freedom and complex geometries. We specialize in aerospace, defense, robotics, medical, industrial, and other sectors where high-performance, custom metal parts are essential.

Norck's Engineering Edge: Pushing the Limits of Metal 3D Printing

- Design for Additive Manufacturing (DfAM): Collaboration to create topologically optimized parts, lattice structures, and achieve geometries impossible with traditional manufacturing.

- Simulation & Analysis: Predicting thermal stresses, optimizing support structures, and preventing build failures for cost-effective production.

- Rigorous Quality Control: In-process monitoring, material analysis, and dimensional inspection for consistent, high-performance parts.

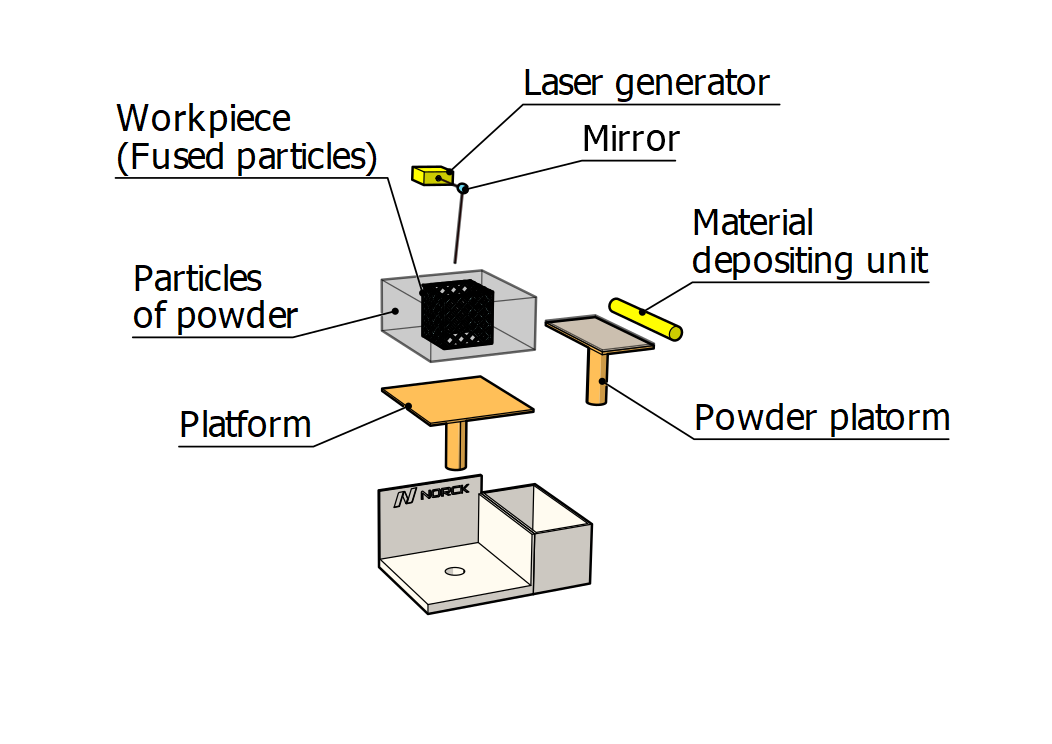

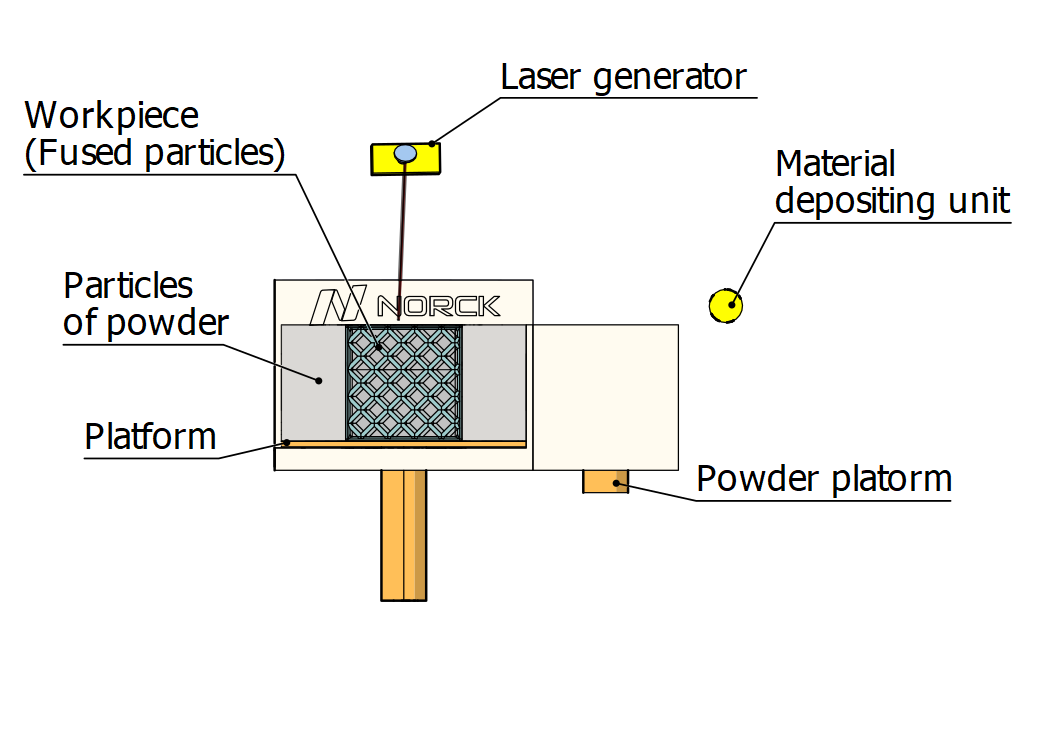

What is direct metal laser sintering?

Direct metal laser sintering is an additive manufacturing process in which particles from a bed of metallic powder are fused to produce parts and assemblies. It helps turn designs into scaled prototypes as close to the designed model. It is mainly used in the earliest stages of product development and can be used in conceptual models, functional prototypes, tooling, electronics, jewelry, and medical industries.

3D printing requires 3D CAD models to print a part or assembly. The 3D models can be made using parametric CAD software such as Solidworks and CATIA V5, or Subdivision modeling software such as 3DS and Blender.

What are the advantages & disadvantages of using direct metal laser sintering?

Direct metal laser sintering is used over other 3D printing processes due to:

• Fast process

• Batch printing

• No need for a supporting structure

• Rigid result

• Accurate features

• Printing precious materials (gold, Platinium, silver)

Although there are disadvantages to using direct metal laser sintering:

• Cooling time

• Post-processing

• No recycling

Norck: Your Data-Driven Partner for On-Demand Manufacturing Excellence

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

- AI-Powered Manufacturing: Data and AI optimize our processes for superior quality, minimized costs, and supply chain visibility

- Vast Production Capacity: Our extensive partner network in Europe and the US guarantees both low and high-volume production.

- End-to-End Expertise: Our team of engineers, data scientists, and product developers ensure design for manufacturability and unparalleled service

- Single-Source Solution: Norck streamlines your supply chain, reduces overhead, enhances purchasing power, and delivers just-in-time results.

- Online DMSL Services: Norck's DMSL services provide a fast, easy, and reliable way to bring your ideas to life with high quality, custom made parts.

- DMSL Services Near You: Your search for DMSL services ends here. Norck offers tailored engineering and manufacturing support that begin with your unique project needs. Whether you're a local business or searching online, our expert team delivers top-quality, customized DMSL solutions to bring your designs to life.

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

English

English