What are the advantages of CNC grinding?

CNC grinding offers more advantages over traditional grinding methods:

• Higher accuracy: CNC grinding offers tight tolerances that can reach ±1µin (±0.025µm).

• More consistent: It is a more consistent process since it is controlled via a computer.

• Higher surface finish: CNC grinding offers smoother surfaces that can reach Ra 2µin 0.05µm

How is it fabricated?

There are several types of CNC grinding, such as:

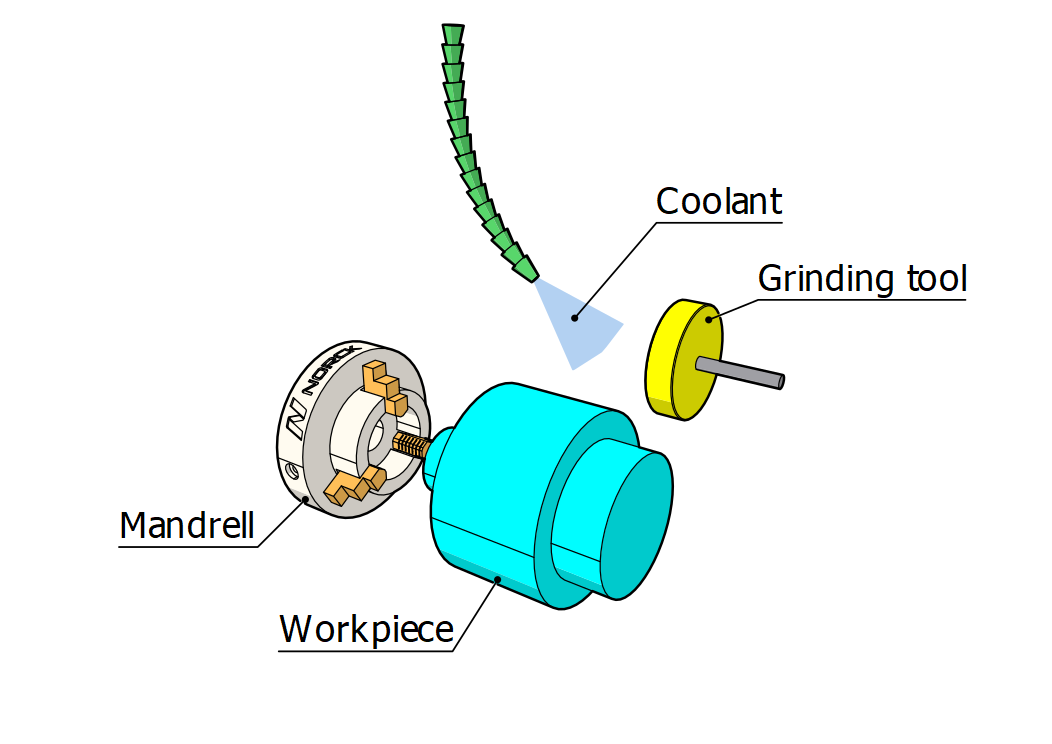

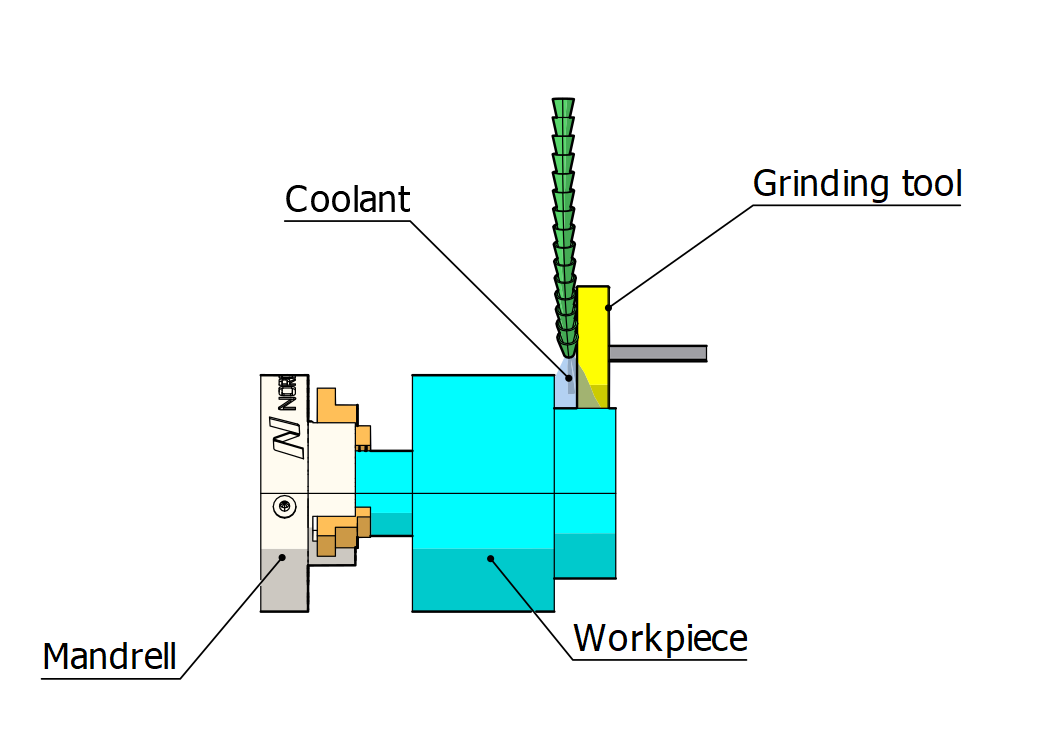

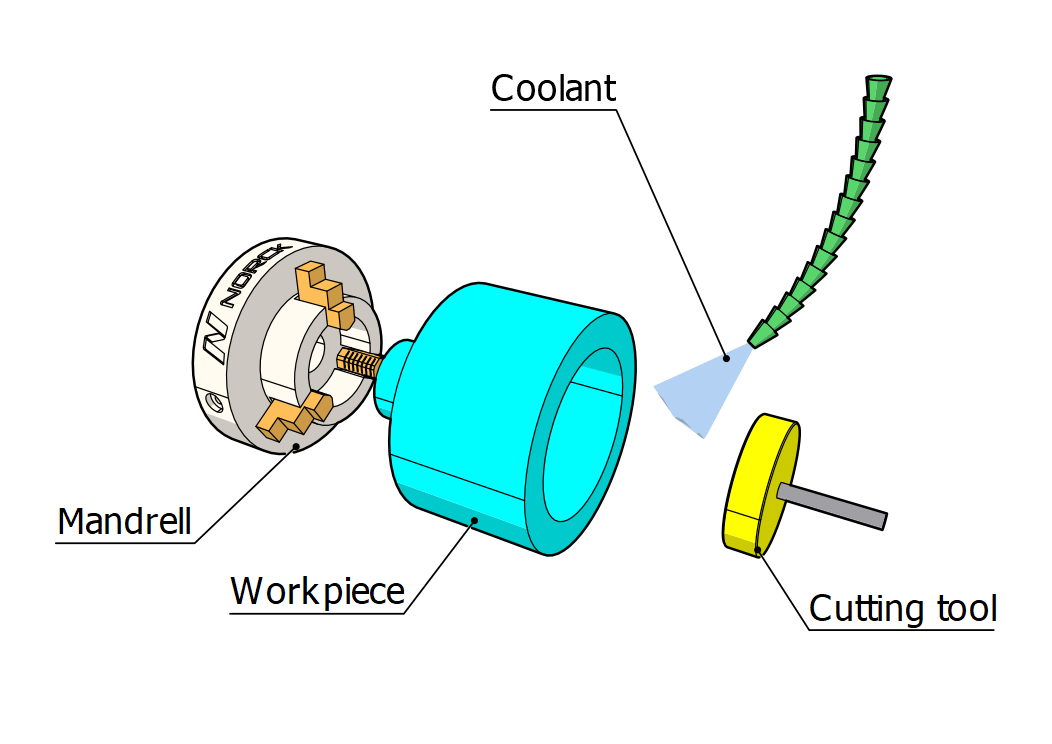

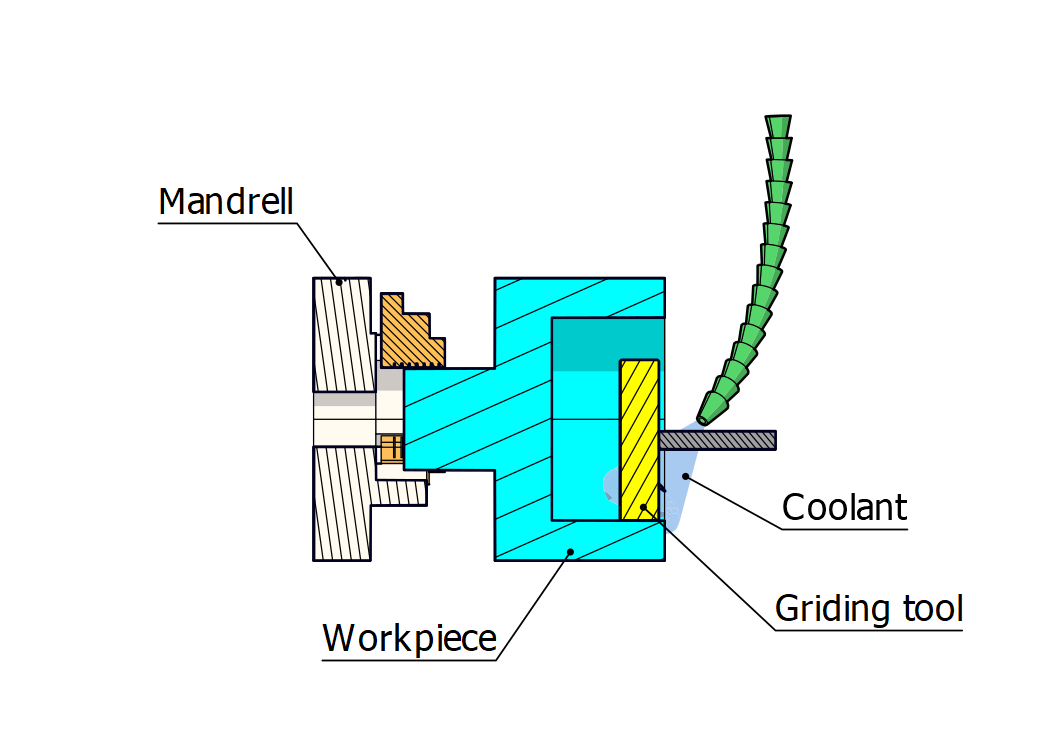

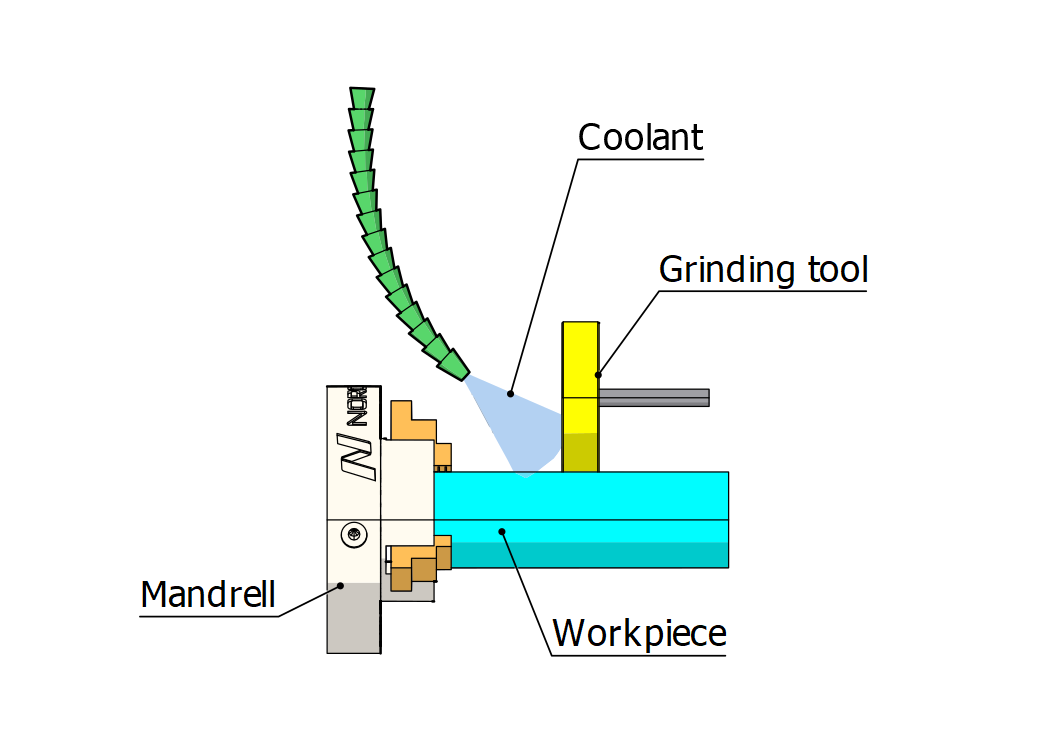

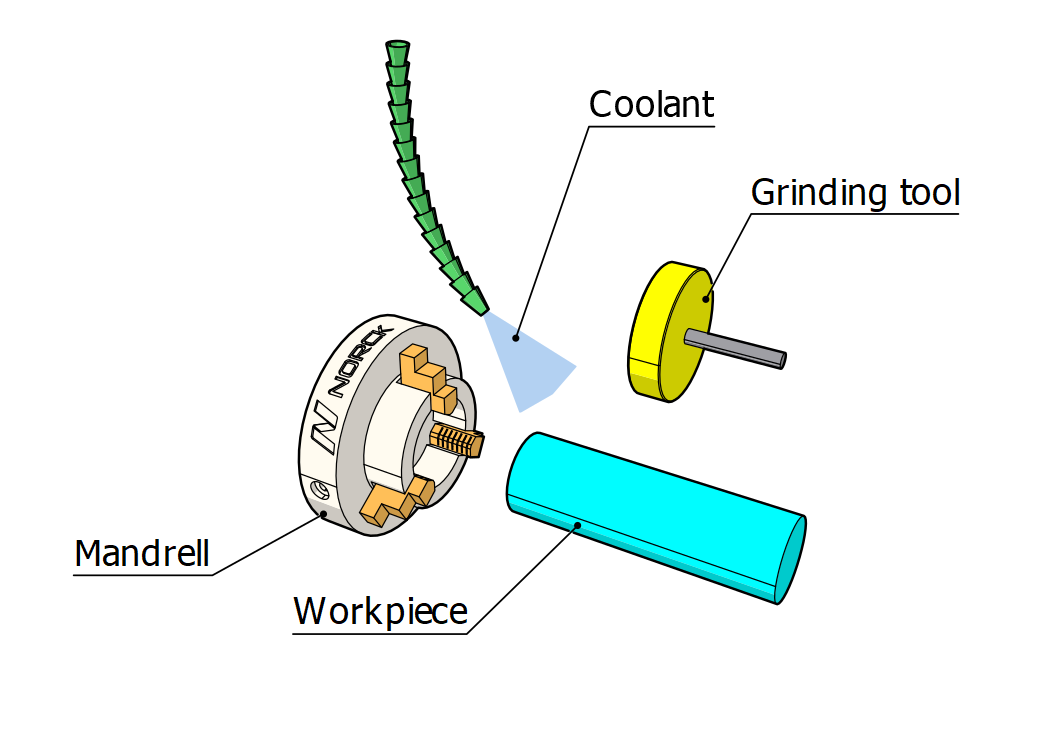

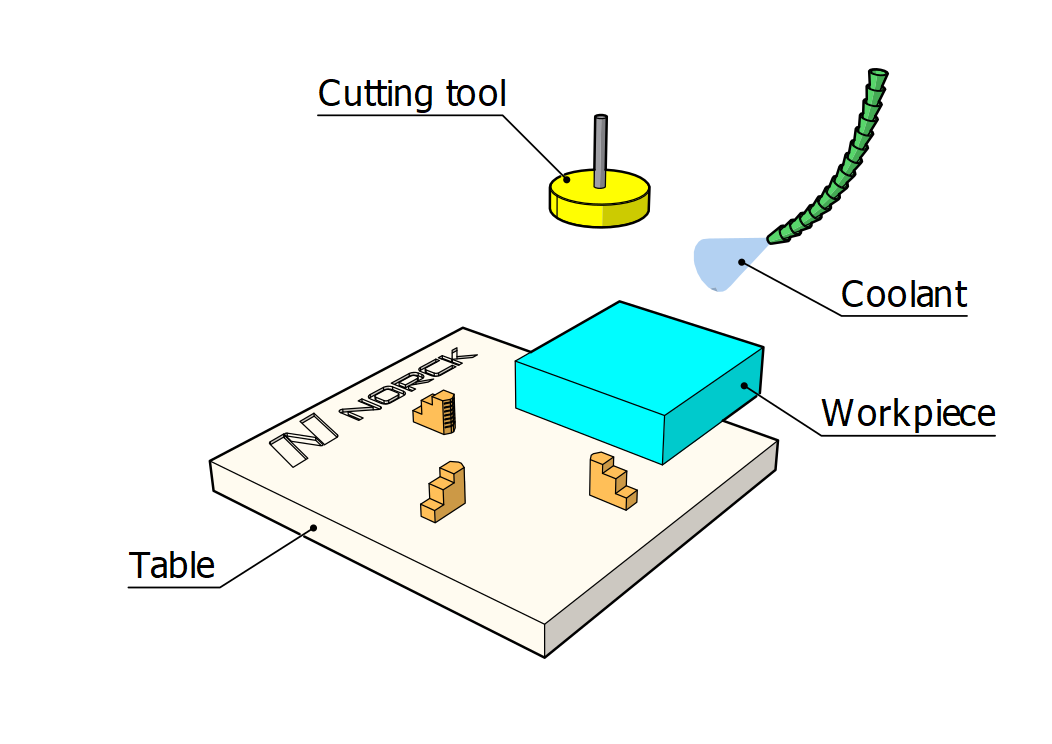

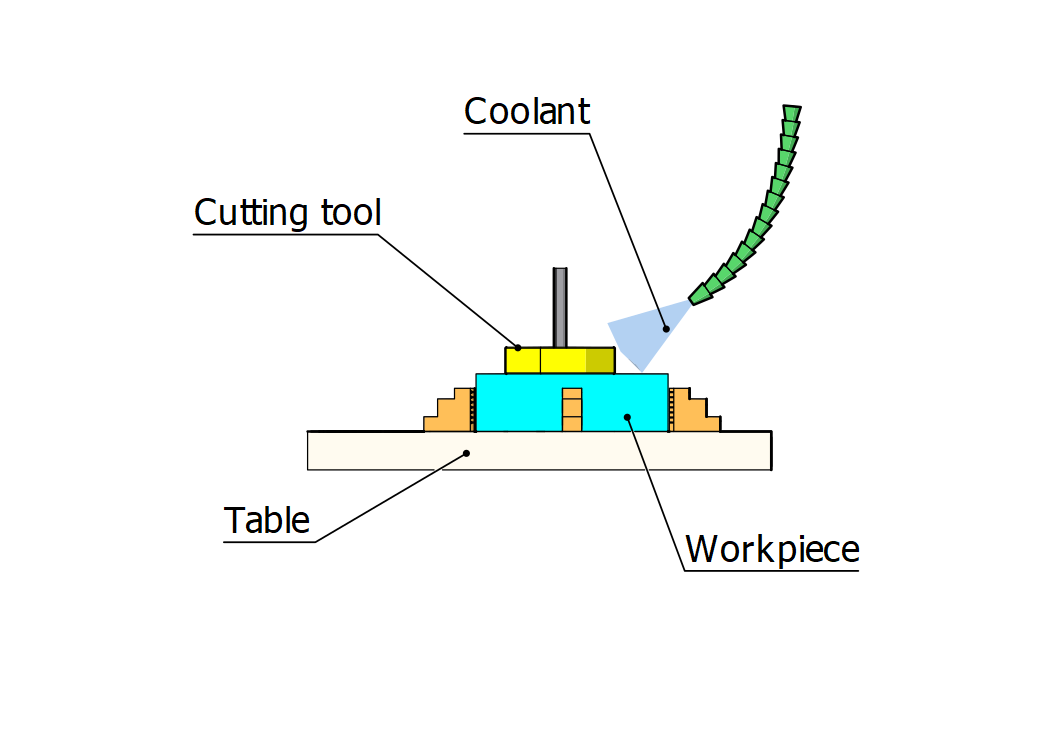

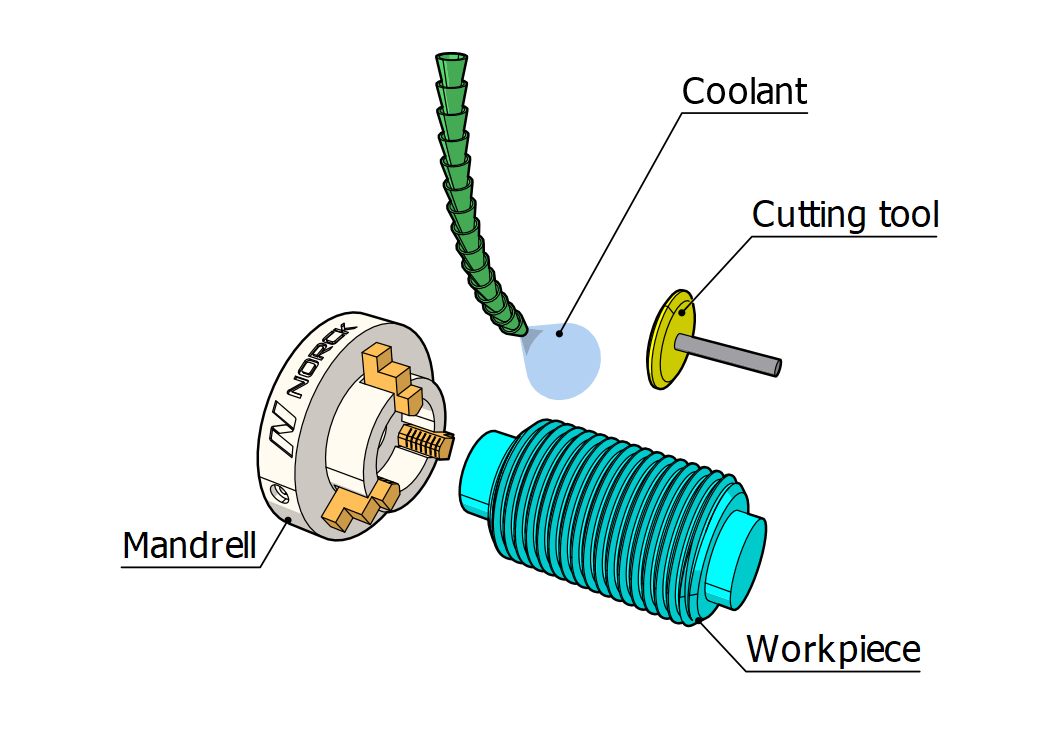

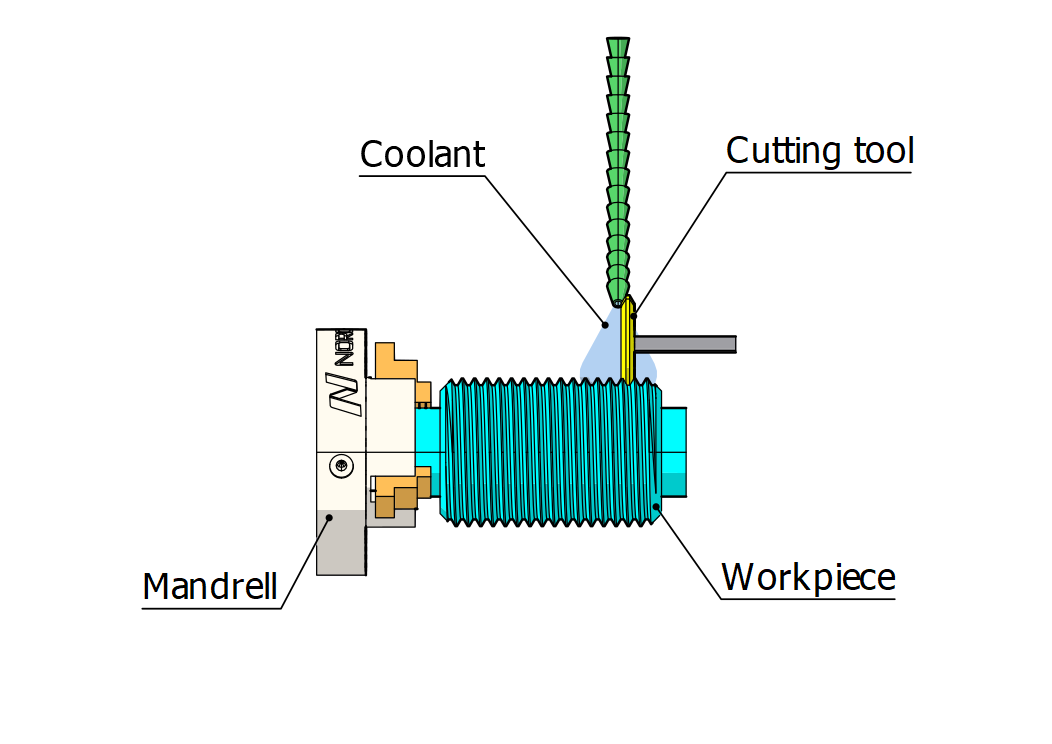

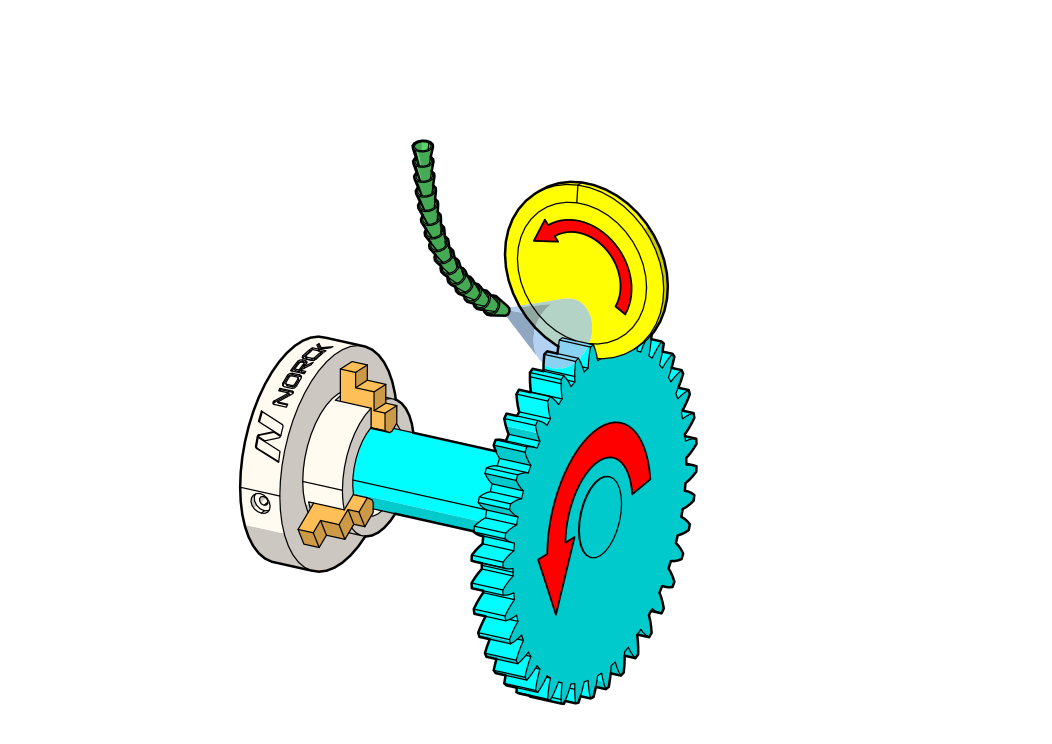

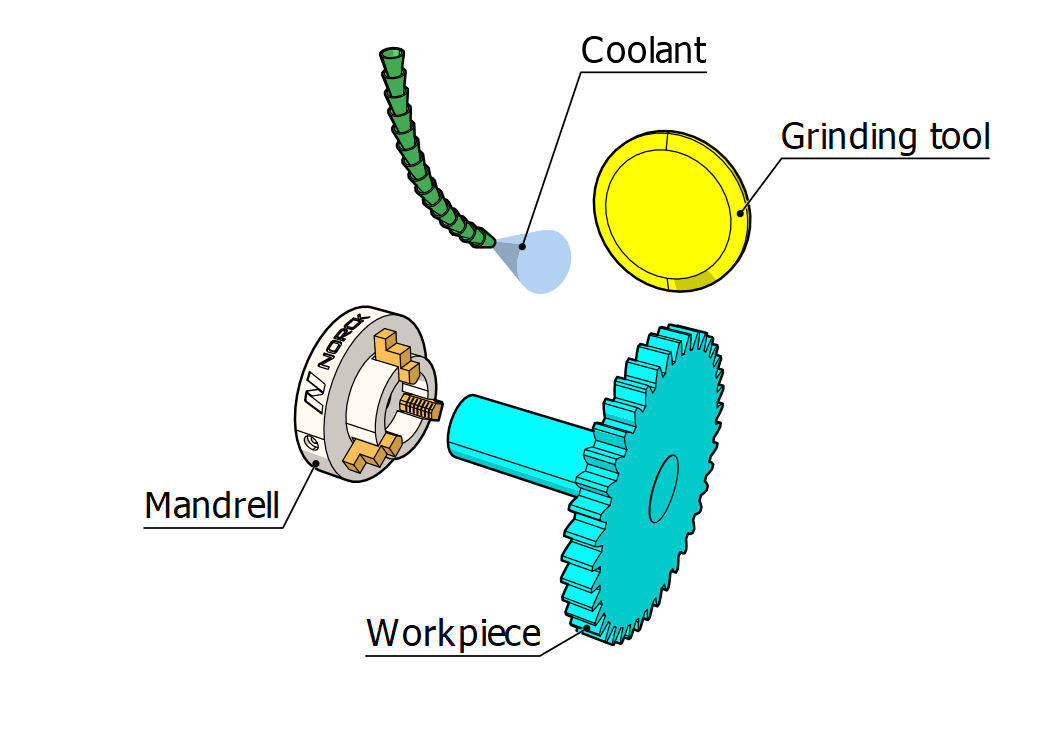

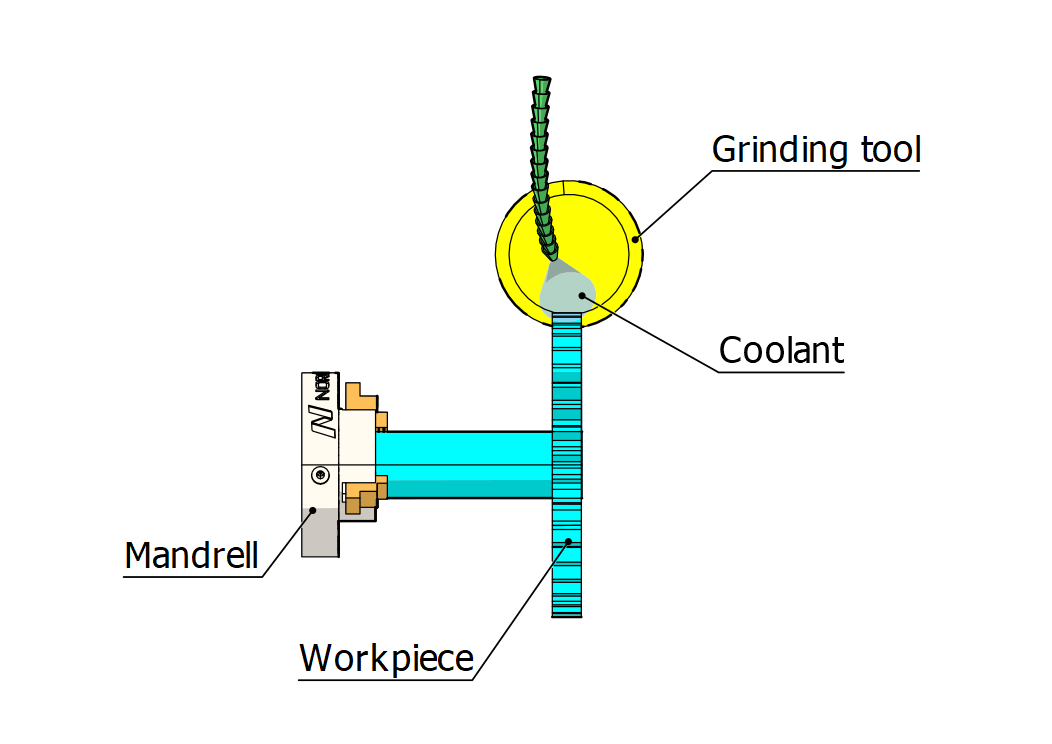

1. Revolving parts : In this process, the workpiece is held in a mandrel and it rotates at high speed. A grinding wheel is then used to remove a thin layer of material while the part is in high rotation. A coolant supply is constantly poured onto the grinding wheel to cool it down. CNC grinding can be used for cylindrical parts, whether centric such as shafts, cylinders, and disks, or eccentric parts, such as crankshafts and camshafts.

Cylindrical grinding can be made for a cylinder's internal and external surfaces.

English

English