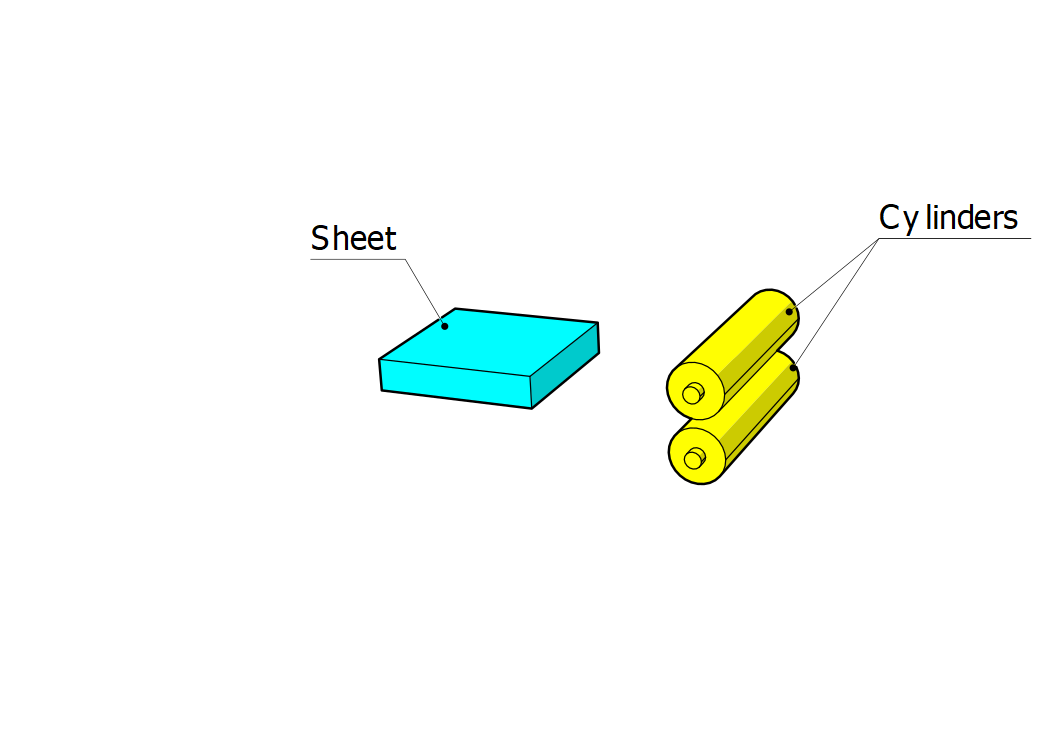

What is sheet metal squeezing?

Sheet metal squeezing is a process that is used to reduce the thickness of a sheet of metal by applying a compressive force to it. Squeezing sheet metal using cylinders is a process similar to traditional sheet metal squeezing, but it utilizes cylinders instead of a punch and a die to apply the compressive force. The process of squeezing can be performed on various materials, such as steel, aluminum, and brass.

Norck: Your Data-Driven Partner for On-Demand Manufacturing Excellence

Norck is a technology-powered manufacturing leader specializing in CNC machining, 3D printing, sheet metal fabrication, and injection molding. Our intelligent, data-driven approach ensures exceptional quality, optimized costs, and seamless supply chain management for companies worldwide.

Key Services:

Why Choose Norck?

- AI-Powered Manufacturing: Data and AI optimize our processes for superior quality, minimized costs, and supply chain visibility

- Vast Production Capacity: Our extensive partner network in Europe and the US guarantees both low and high-volume production.

- End-to-End Expertise: Our team of engineers, data scientists, and product developers ensure design for manufacturability and unparalleled service

- Single-Source Solution: Norck streamlines your supply chain, reduces overhead, enhances purchasing power, and delivers just-in-time results.

- Online Sheet Metal Squeezing Services: Norck's online sheet metal squeezing services provide a fast, easy, and reliable way to bring your ideas to life with high quality, custom made parts.

- Sheet Metal Squeezing Services Near You: Your search for sheet metal squeezing services ends here. Norck offers tailored engineering and manufacturing support that begin with your unique project needs. Whether you're a local business or searching online, our expert team delivers top-quality, customized sheet metal squeezing solutions to bring your designs to life.

Experience the Norck difference. Get a quote fast for your manufacturing needs today!

English

English