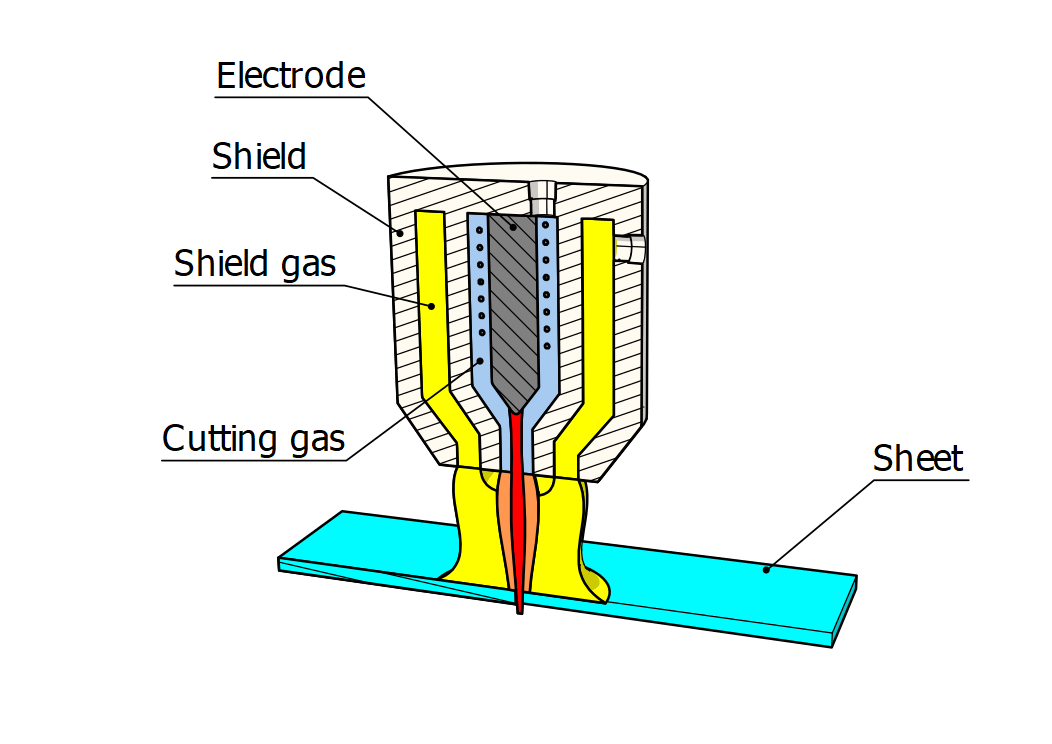

The term plasma designates a state of matter (solid, liquid, gas, and plasma). It consists of electrically charged gas, created when a gas is heated or when you pass electricity through it, such as fire, lightning, and neon light.

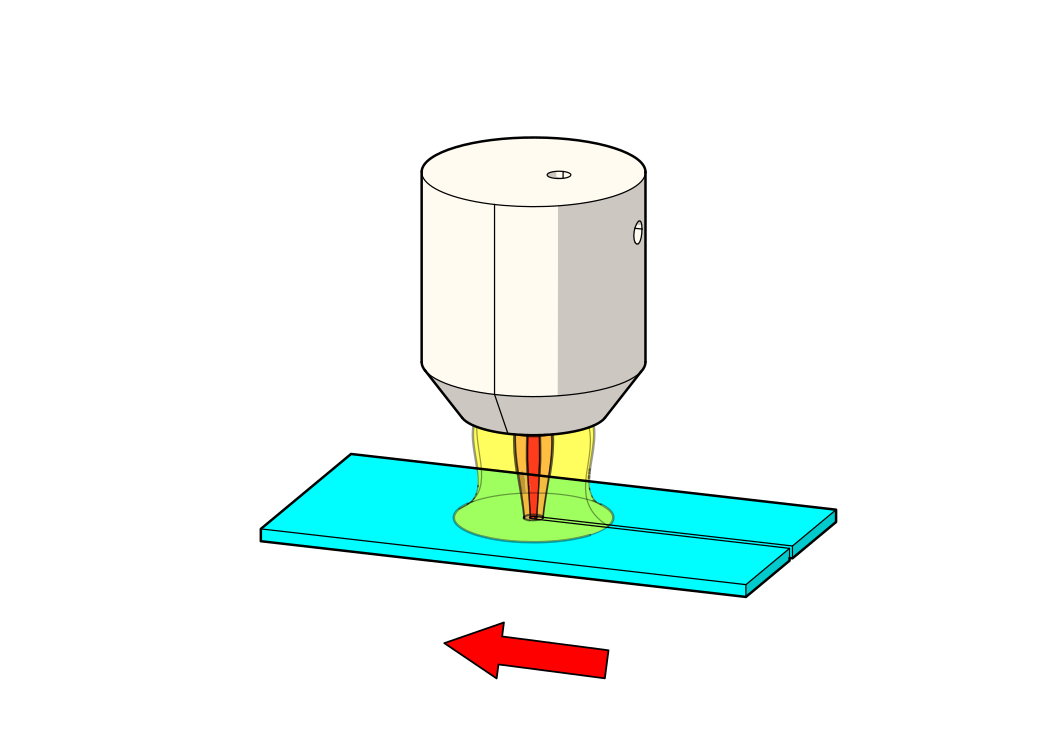

Plasma cutting is a process that jets gas at high temperatures to cut through electrically conductive materials. Plasma can cut steel, stainless steel, aluminum, brass, and copper. It is widely used, from art and custom-made tools to aeronautic and automotive industries.

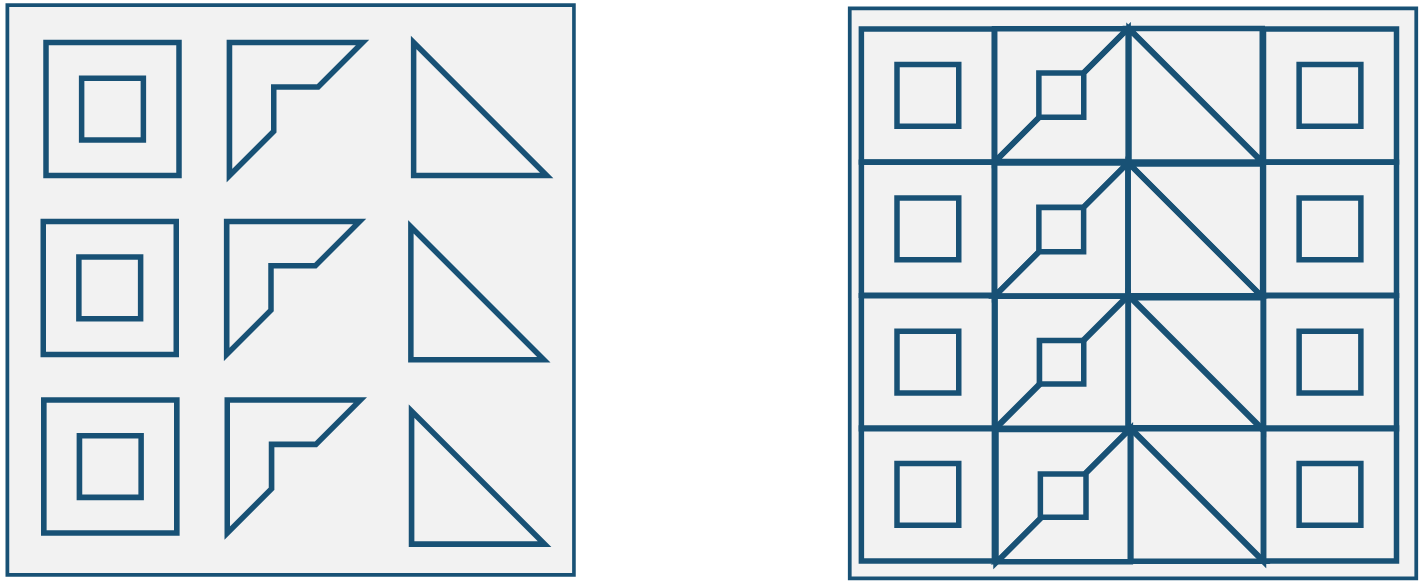

At Norck, we use plasma cutting to cut tubes and bent sheet metal components to clean edges and add holes.

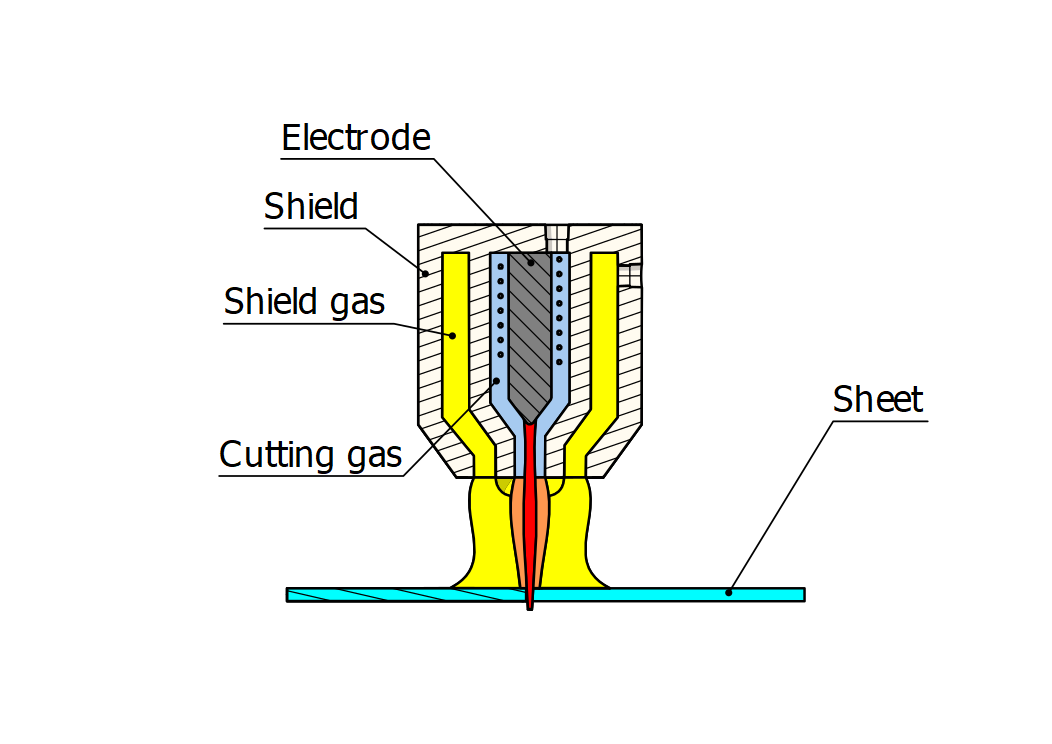

Plasma cutting is always perpendicular to the sheet surface, so it can’t add drafts or threads.

English

English