Most of the sheet metal cutting operations are performed as cold. Norck offers sheet metal cutting and forming processes as described below:

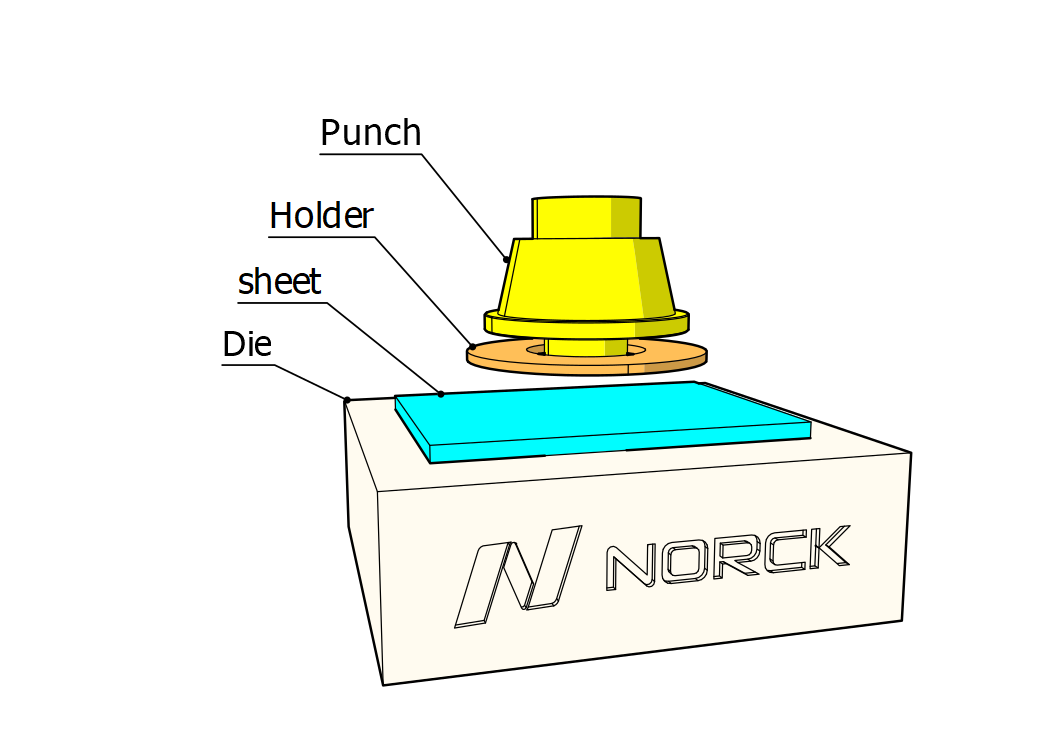

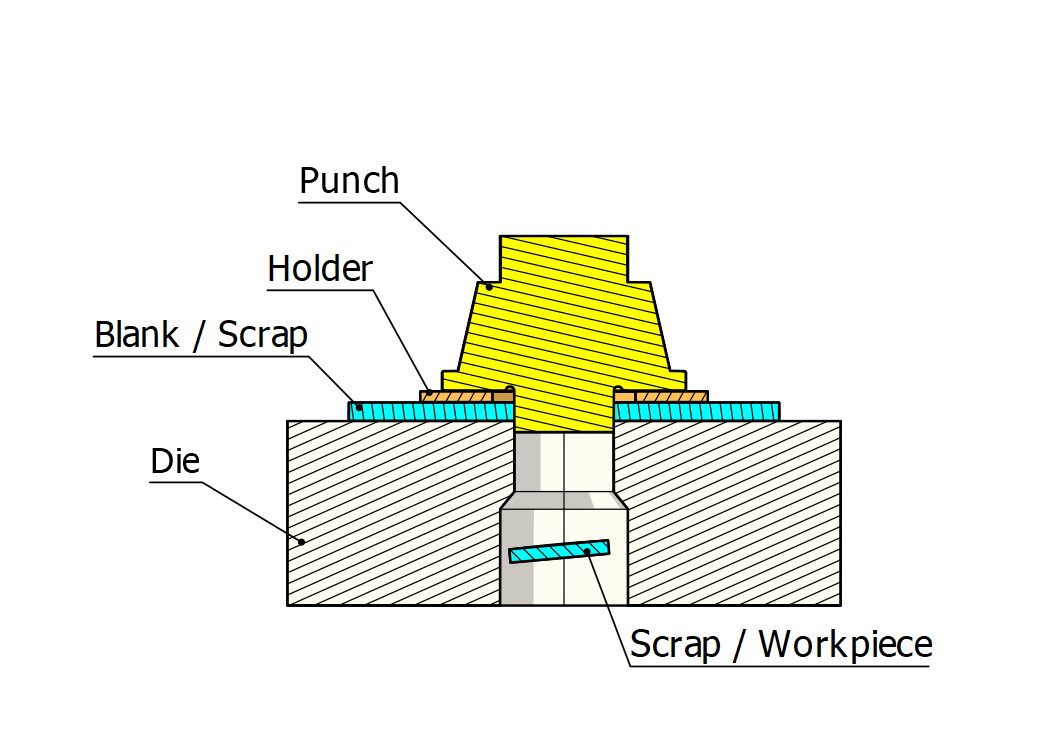

• Blanking / Punching:

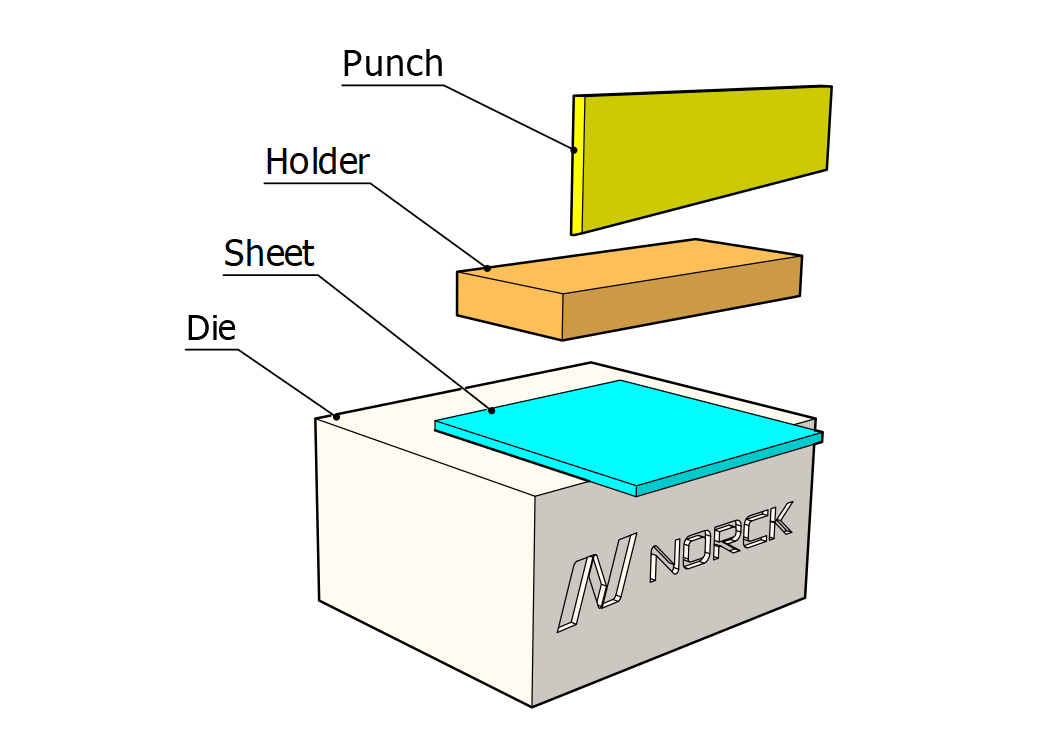

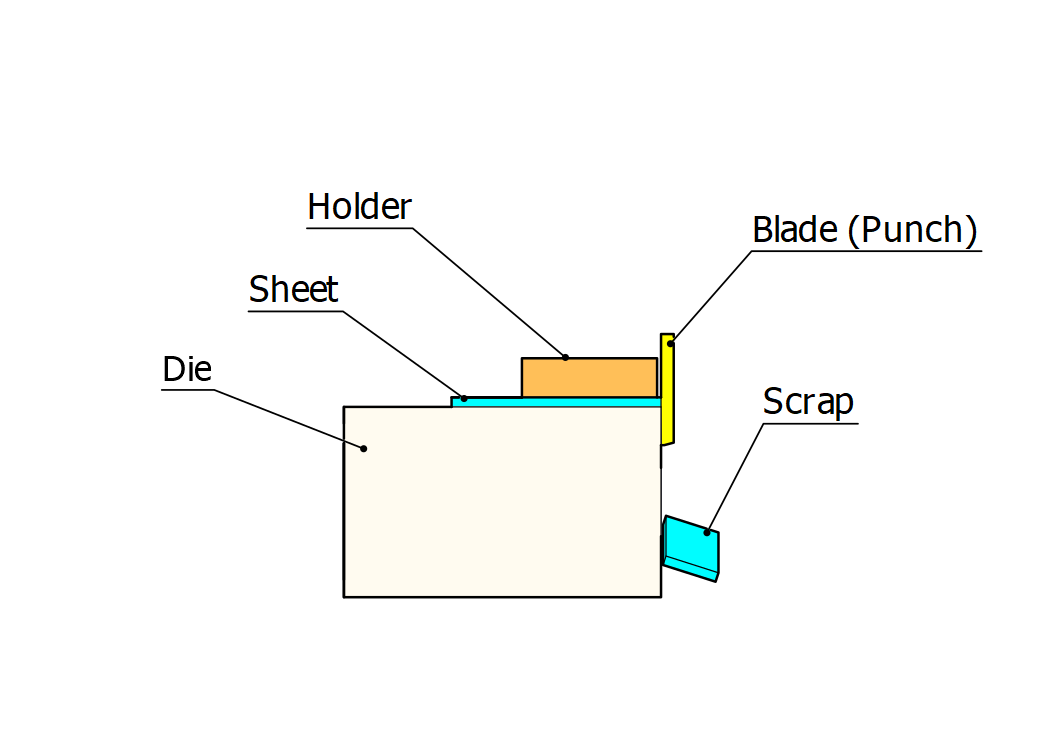

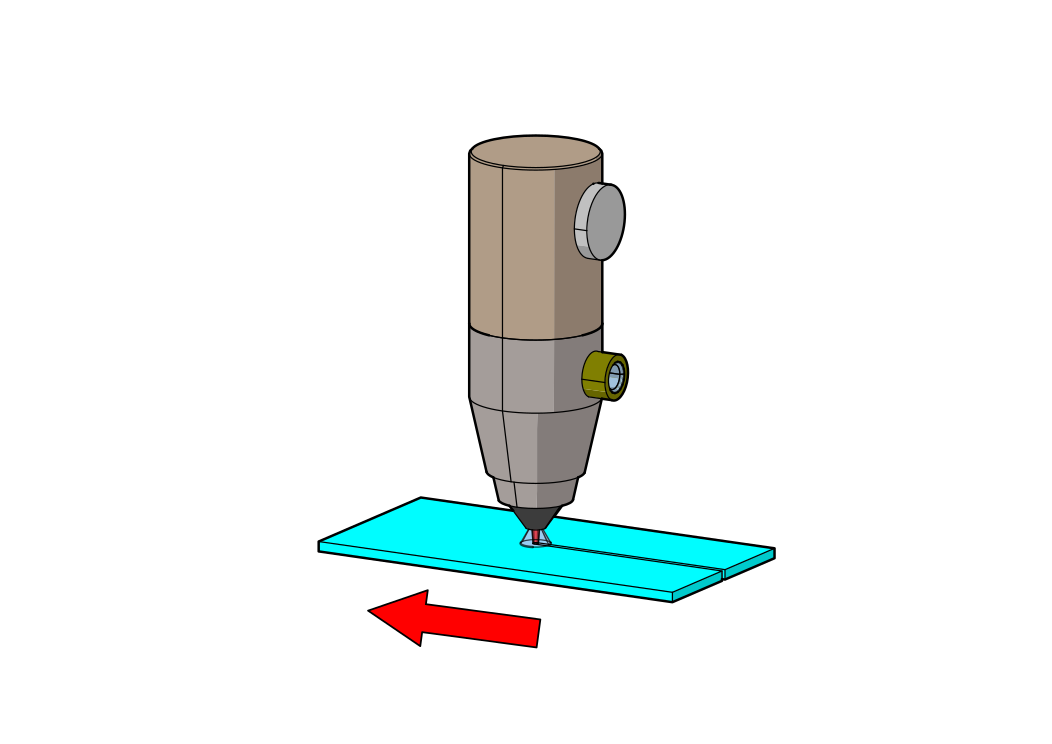

Blanking and punching are cutting processes of a workpiece from a sheet metal coil using a press (DIE). This process is mainly used in mass production fields such as automotive. The significant variables are the punching force, the die and punch materials, and the number of parts produced per minute.

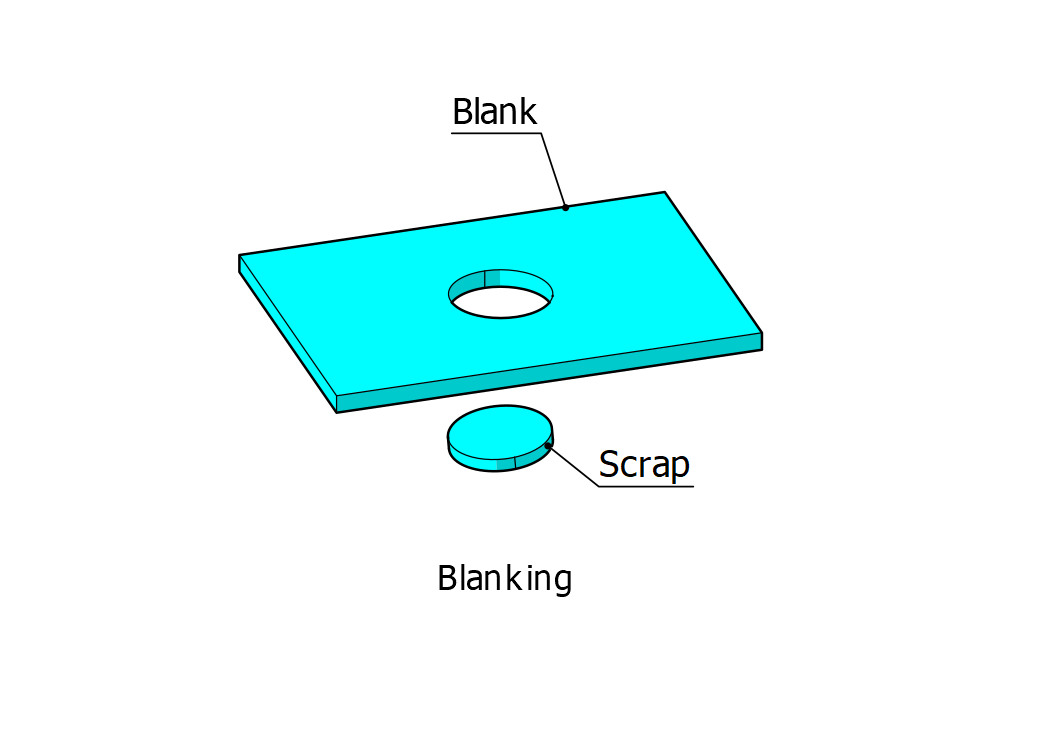

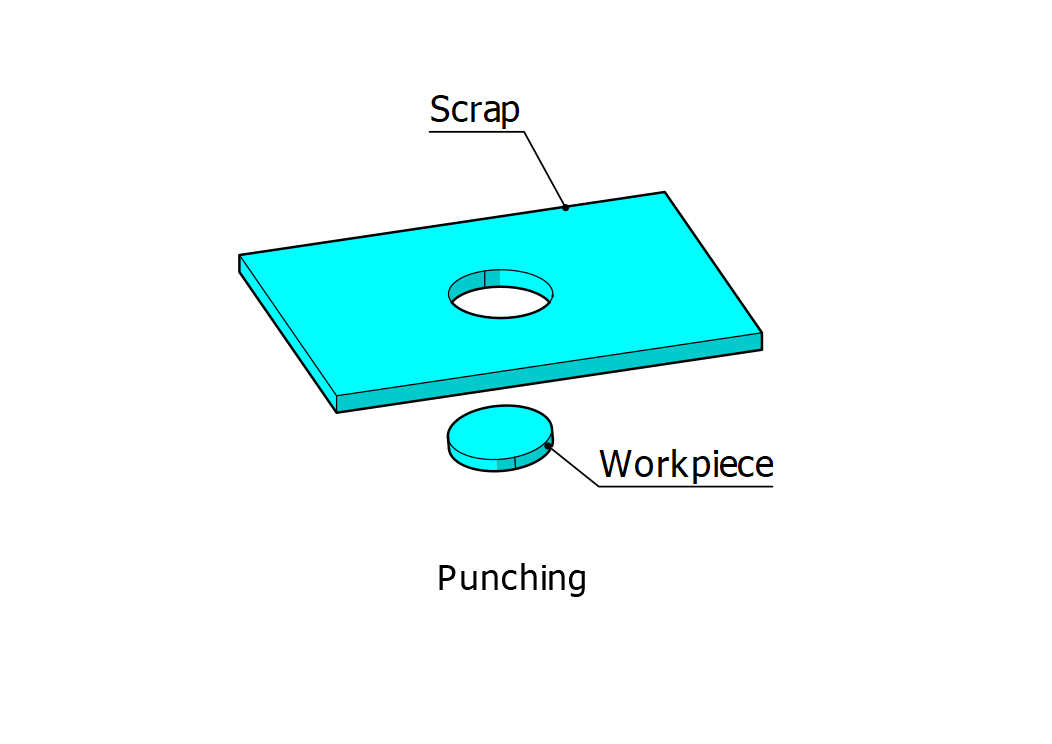

A scrap is removed from the sheet metal to produce the workpiece (blank) in blanking. On the contrary, in punching, a workpiece is punched from the sheet metal, and the left is scrap. Norck will help you nest your parts to get the most cost-effective process.

In both processes, clearance is a significant factor in cutting. It is the distance between the cutting edges(die and punch), and it depends on the elasticity and thickness of the material. With higher clearance, rollover and burns can occur. With a lower clearance, a secondary shear can occur. Norck has an expert team that will guarantee you a perfect cut each time.

English

English