Norck's Engineering Edge: It's About Performance and Precision

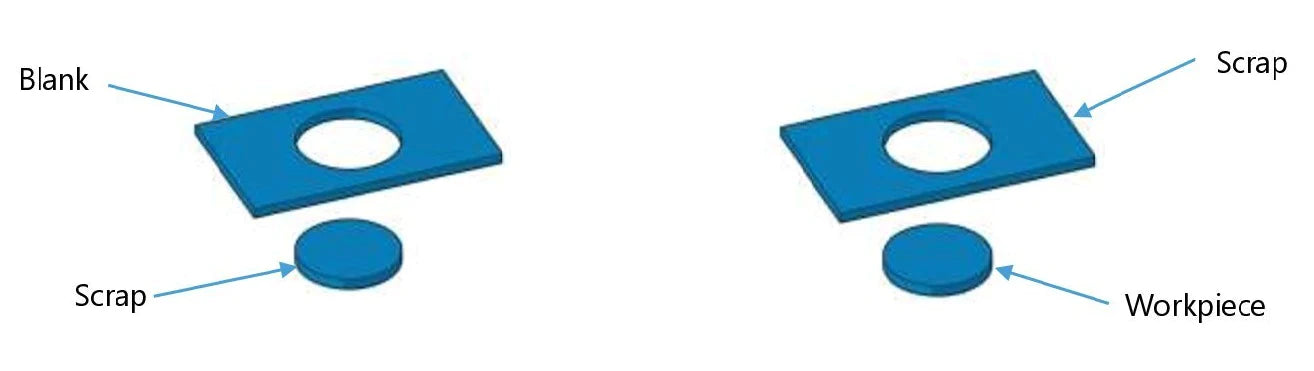

- Design for Manufacturability (DFM): Early collaboration to optimize your part design for efficient stamping, reducing costs and minimizing scrap.

- Material Expertise: Guidance on selecting the optimal sheet metal for formability, strength, corrosion resistance, and cost targets.

- Process Optimization & Simulation: Fine-tuning stamping parameters and tool design using FEA modeling for intricate forms and tight tolerances.

- Rigorous Quality Assurance: Dimensional inspection, material verification, and in-process monitoring to ensure consistent quality across production runs.

English

English